Electric vehicles and the 12V battery

Different types of electric cars and their dependence on the 12V battery

The success of the automobile as a means of individual transportation began in 1913, with the introduction of the then revolutionary assembly line production by Henry Ford. Even a century later, most cars on our roads are still based on the principle of the internal combustion engine, which has been continuously improved by engineers and nowadays combines high performance, low consumption, and long durability.

Increasingly complex engine technology and, at the same time, stricter emissions regulations have triggered a technological leap that has led to the electrification of the drivetrain today. But not all electric vehicles on the market are the same. Depending on the requirements and vehicle segment, there are different approaches to electrified mobility.

What is an xEV?

- HEV – Hybrid Electric Vehicle

- PHEV – Plug-in Hybrid Electric Vehicle

- BEV – Battery Electric Vehicle

- FCEV – Fuel Cell Electric Vehicle

Hybrid Electric Vehicles. The best of both worlds?

The term hybrid only means that there is more than one energy source for the operation of the vehicle. In fact, vehicles with Start-Stop technology are already considered "micro-hybrid" vehicles, because here the 12V battery acts as a second energy source when the engine is switched off.

The evolution of the "micro-hybrid" was the so-called "mild-hybrid", in which a 48V Li-ion battery is installed to supply particularly energy-hungry consumers. Although these two systems are already called hybrids, they lack a crucial feature that has long been associated with "hybrid electric cars": Purely electric driving without the aid of the combustion engine.

The difference between Full Hybrid and Plug-in Hybrid Vehicles

The term "Hybrid Electric Vehicle" actually describes two different concepts. The "Full Hybrid Electric Vehicle" (FHEV, usually abbreviated to HEV) and the "Plug-in Hybrid Vehicle" (PHEV). Both approaches share the fact that the vehicles have a high-voltage lithium-ion battery and can thus be driven purely electric.

The difference between the two systems lies in the charging strategy for the high-voltage battery. In an HEV, the battery can be charged exclusively by the combustion engine or by brake energy recovery (recuperation). In a PHEV, the battery can also be charged at a charging station, as in a purely Electric Vehicle, hence the term "Plug-in". Due to the limited charging possibilities, the capacity of the drive battery in an HEV is generally smaller than in a PHEV. Due to the lower capacity of the battery, the distances that can be covered purely electrically are also shorter for an HEV than for a PHEV.

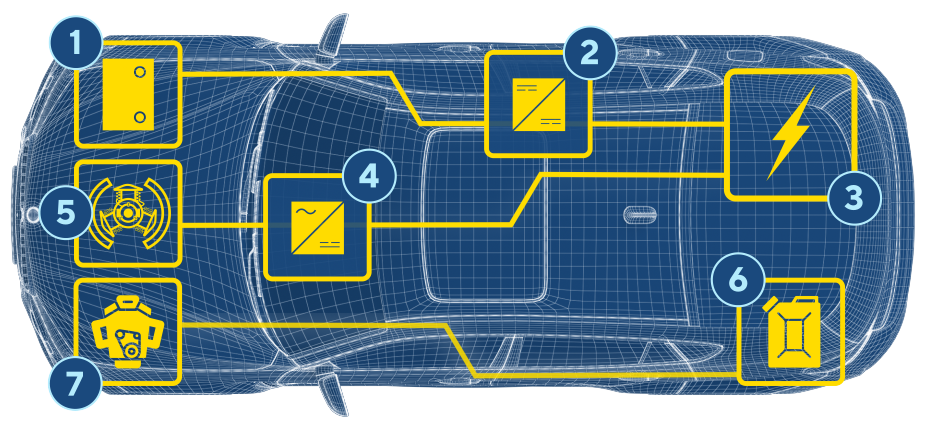

- 12 Volt Battery

- DC/DC Converter

- High-voltage Battery

- AC/DC Converter

- High-voltage traction motor

- Petrol or diesel tank

- Internal combustion engine

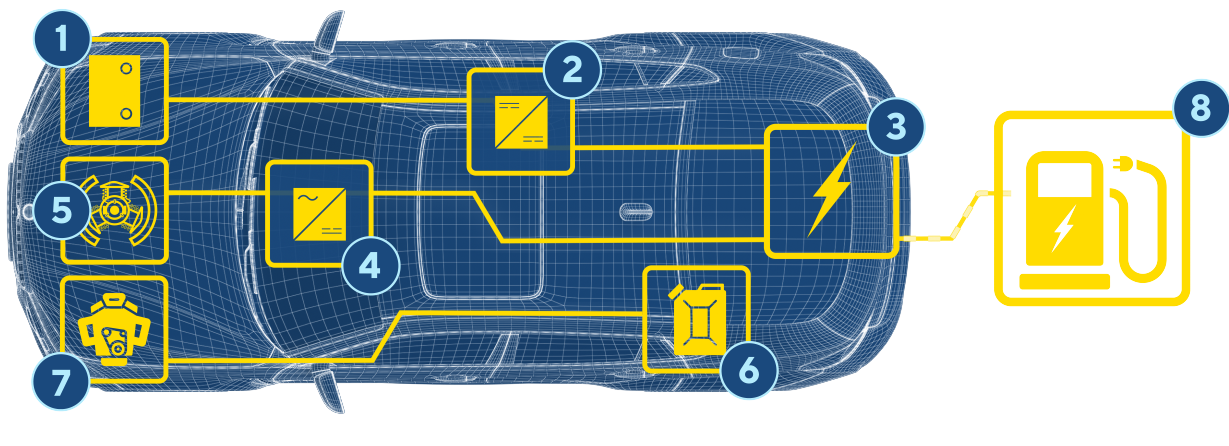

PHEV body, with smaller fuel tank but larger battery with external charging port for longer electric range.

- 12 Volt Battery

- DC/DC Converter

- High-voltage Battery

- AC/DC Converter

- High-voltage traction motor

- Petrol or diesel tank

- Internal combustion engine

- Electrical power source (charging station/wall box)

Both systems enable purely electric and thus local emission-free driving. Thanks to the additional combustion engine, the vehicle can also be used for long distances without restrictions. If the combustion engine is not used, a hybrid electric vehicle behaves like an all-electric car.

Pros and cons of HEVs and PHEVs

- Reduction of fuel consumption and thus lower operational costs

- Local emission-free driving

- High torque via the electric motor when starting and accelerating

- Less noise emissions during purely electric drive

- More expensive than a comparable vehicle with a combustion engine only

- More complex propulsion system, therefore potentially higher maintenance costs

- Higher vehicle weight due to traction battery and additional components

- Smaller boot space for some vehicles, as space is needed for the high-voltage battery

The all-electric future: Battery Electric Vehicles and hydrogen-powered cars

Today, all signs point to electric drive systems as the propulsion system of the future. However, it is not yet clear which energy storage system will prevail. The development of lithium-ion battery technology and fuel cells is currently highly dynamic, so that enormous progress is currently being made in both areas. In addition to technical innovations, both areas are concerned with scalability and cost reduction in production.

The focus of technical developments in traction batteries continues to be an increase in energy density. The aim is to make the batteries smaller and lighter while maintaining the same capacity, i.e., the same driving distance of the vehicle. At the same time, efforts are being made to optimise the chemical composition of the battery cells to reduce the percentage of critical metals, such as cobalt to a minimum.

Even though there are already some hydrogen-powered cars on the market, the mass production of fuel cell drives is still further away than that of lithium-ion batteries. Current development is focused on reducing the need for platinum in the fuel cell to significantly lower costs. Further progress is being made in making the fuel cell membrane more robust and durable.

Apart from the energy storage system, the powertrain architecture of Battery Electric Vehicles (BEVs) and Fuel Cell Electric Vehicles (FCEVs) is largely comparable.

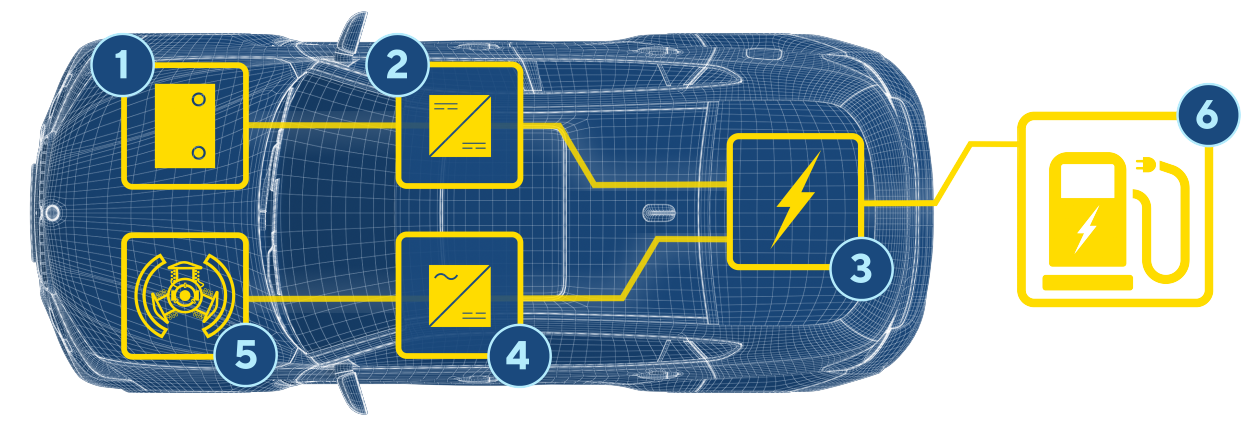

- 12 Volt Battery

- DC/DC Converter

- Large high-voltage LiIon battery

- AC/DC Converter

- High-voltage traction motor

- Electrical power source (charging station/wall box)

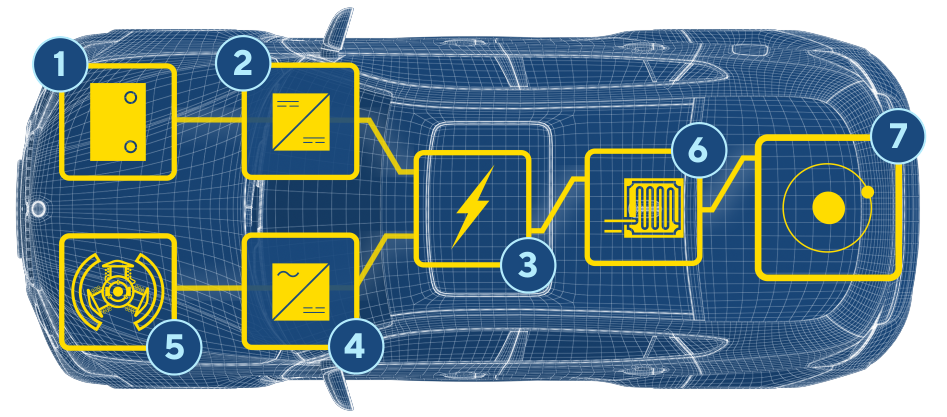

The FCEV uses a hydrogen tank, a fuel cell, and a small Li-ion battery as intermediate storage to power the electric drive.

- 12 Volt Battery

- DC/DC Converter

- Large high-voltage LiIon battery

- AC/DC Converter

- High-voltage traction motor

- Fuel cell

- Hydrogen tank

Pros and Cons of BEVs and FCEVs

- Less complex drivetrain than HEVs, thus potentially lower maintenance costs

- High torque and good driving dynamics through pure electric drive

- Local emission-free driving

- With BEV: Low operating costs in connection with a private photovoltaic system

- Less extensive network of hydrogen fuelling stations and charging stations compared to conventional petrol stations

- Long "refuelling" for BEVs

- Many models only partially suitable for long-distance use

- Without subsidies, more expensive than comparable conventional vehicles with combustion engines

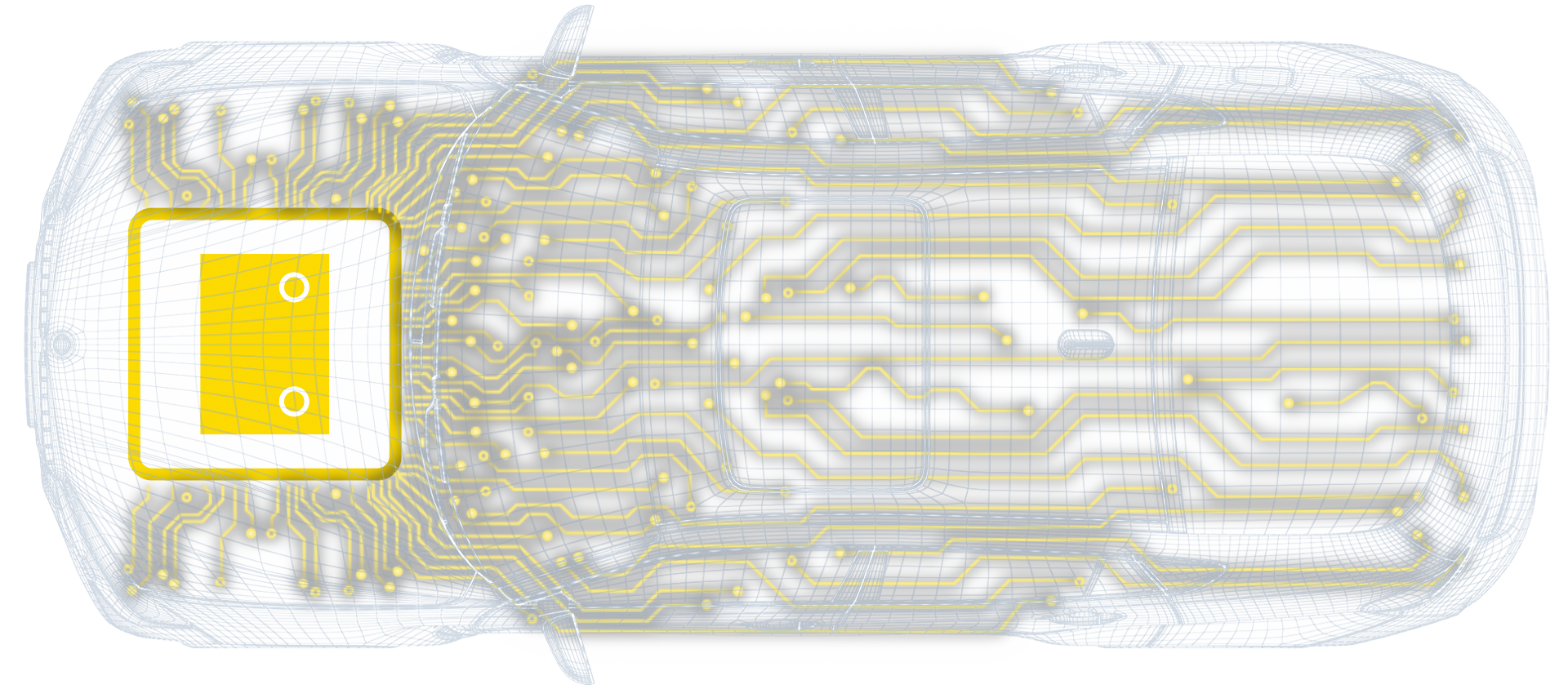

The low-voltage system in every Electric Vehicle

The vehicle's 12V network supplies comfort functions, control units, sensors and actuators.

To still call it a starter battery in modern vehicles, regardless of whether they have an internal combustion engine or are "fully electric", does not do justice to the tasks of the 12V battery. In this article, we have detailed the tasks that the battery handles in addition to the actual starting of the vehicle.

Conclusion

The automotive future is electric. Currently, different concepts are available simultaneously each with their own advantages and disadvantages. The customer is thus spoilt for choice when it comes to choosing the most suitable concept for his or her individual needs. Hybrid concepts combine the best of both worlds. On the one hand, they offer long range thanks to very efficient combustion engines, the possibility of local emission-free driving and high torque right from the start because of the additional electric drive. On the other hand, the already complex drive and exhaust treatment system becomes even more complex due to the electric components.

Most electric cars today rely on a large Li-ion high-voltage battery for energy storage. Long ranges are still limited to premium vehicles with large traction batteries. However, current research aims to further improve the range and to dispense with critical metals. Technical advances and more efficient large-scale production will also be able to further reduce the cost of the battery, so that "electric cars" will become competitive in other vehicle segments. The use of hydrogen as an energy storage medium is another promising approach for the future of the automobile and could help to overcome the two major drawbacks of today's battery electric cars: the heavy traction battery and the long charging times.

Which concept will prevail in the future cannot be predicted with certainty at this point. It is clear, however, that apart from the actual drive concept, there are no further differences between the vehicles. What they all have in common is the electronics installed in the vehicle for comfort and safety systems, which continue to be based on the established 12V electrical system and are supported by a 12V battery.

Find a trusted workshop

Do you work with batteries?

Deepen your knowledge

-

Construction of VARTA Promotive EFB Truck BatteriesA patented mixing element ensures that acid stratification cannot occur in our ProMotive EFB battery. Read our article now to find out exactly how this works and what advantages it brings.

-

The importance of charge acceptance of truck batteriesBatteries with high starting current (CAA) and sufficient capacity (C20) guarantee reliable fleet operation. We tell you why.

-

Battery tips for the leisure seasonGet ready for your journey. Discover helpful tips and tricks for your leisure battery to get the best start to the season

Got a question?

-

Make use of our VARTA Battery Finder to find the battery product that fits your vehicle.

-

43,22% (ADAC Pannenstatistik 2022: https://www.adac.de/rund-ums-fahrzeug/unfall-schaden-panne/adac-pannenstatistik/) of all vehicle breakdowns are caused by battery issues - make sure to eliminate those.

Find a trusted VARTA® Partner near you and get your vehicle battery checked!

-

To extend your vehicle's battery life, consider these tips:

- Charge Care: Regularly monitor and charge the battery, especially during long-term parking or winter storage. Charge every two months if used sporadically.

- Check Charge: Regularly check battery charge, particularly in cold weather or after short trips. Dimming headlights indicate low charge.

- Prioritize Safety: Conserve battery by minimizing non-essential electrical use and keeping safety systems active during long drives.

- Clean Installation: Keep the battery and terminals clean to prevent discharge and enhance charging efficiency.

For more information find our article "Correct battery care"