“The outstanding performance of the AGM technology convinced us.”

Six facts about VARTA® AGM technology:

Mounting flexibility and spillage

The “Absorbent Glass Mat” or in short “AGM” soaks up the acid in the battery like a sponge. This makes the AGM maintenance-free and spill-proof and allows it to be placed in more enclosed or hard to reach areas.

Charging time

Special electrochemical processes inside the battery lead to a much better charge acceptance and faster recharge time. Compared to conventional batteries, AGM batteries can be fully recharged inside the vehicle.

Temperature tolerance

AGM batteries perform better in all temperatures and offer superior cold cranking power.

Depth of discharge

AGM batteries can handle a high level of discharge (80%) ensuring a long lifetime while conventional batteries can be discharged by 20% to achieve similar battery life. A high depth of discharge means a high amount of energy is provided by the battery. This is ideal for vehicles with many power-hungry consumers.

Durability, vibration, and shock resistance

The design and the enhanced fixations at the bottom and at the wall of the container lead to improvements in shock and vibration resistance.

Service life and self-discharge

AGM batteries last longer than conventional lead acid batteries. They have a minimum level of self-discharge for maximum storage capabilities.

“With AGM technology, VARTA® covers today‘s and future demands of trucks and busses.”

Leading OE manufactures consider the VARTA® AGM technology for trucks and busses future proof even for the upcoming generation of vehicles. This includes electric trucks and functional safety systems like autonomous driving where AGM batteries remain the power-source of choice to supply all 24V consumers, which are crucial for the vehicles reliable functionality.

“We really put the VARTA® AGM technology to the test. By partnering with the Russian racing team KAMAZ Master for the Rallye Dakar we found an application with the highest demands regarding durability, resistance, and reliability”, says Clarios’ Thorsten Werle.

The most famous race around the globe is known for its extreme conditions for the teams, their vehicles, and their spare parts. In recent years VARTA® AGM technology successfully met all the Dakar’s challenges and proved that this technology is the most reliable and resilient in the market.

“AGM outperforms conventional battery technologies.”

Krystof Leporowski, Senior Service Technician Elkor Transport

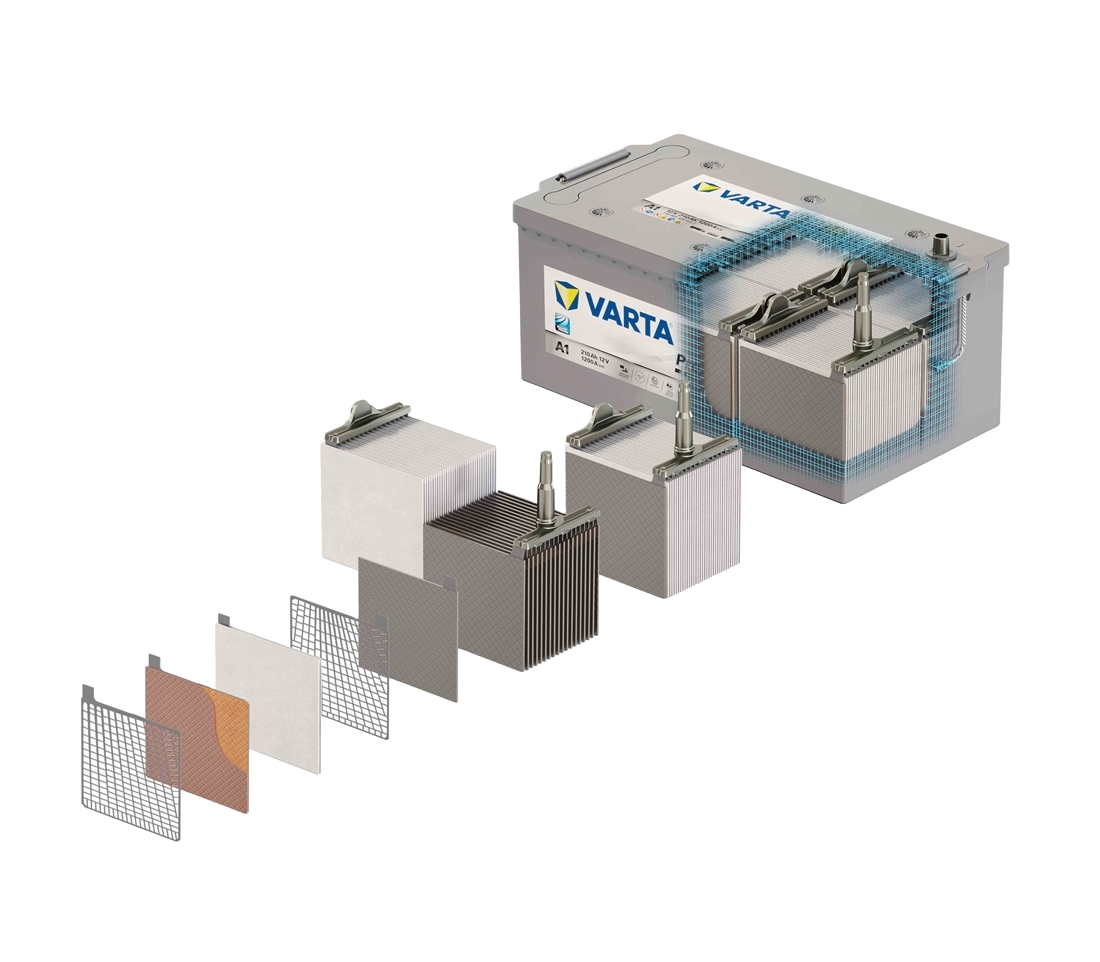

“AGM stands for Absorbent Glass Mat. The electrolyte inside the cells is bound in the name giving glass fleece like water in a sponge, providing high cyclic stability”, explains Thorsten Werle, Engineering Design Lead Heavy Duty at Clarios EMEA.

This allows the AGM battery to be repeatedly charged and discharged without any loss of performance. Since there is no free acid inside the battery, the risk of acid stratification and thus a loss of capacity is being avoided."

“The VARTA® ProMotive AGM battery increases the battery cycling capabilities by six times compared to standard battery solutions and provides the ability to operate at levels of discharge close to 80%. Conventional batteries can only manage 20%. With an extraordinary charge acceptance an AGM recharges up to 100% in less than one hour, if it was discharged down to 50% before. Conventional batteries need nearly three times as long. This is part of the strength of the AGM technology.”

Moreover, additional stabilizing fixations lead to the best vibration resistance in class, which make AGM batteries the perfect fit for all EURO 5 & 6 vehicles. A feature that is particularly appreciated by logistics companies:

“Due to extended fuel tanks and AdBlue containers, batteries were moved to end-of-frame where they are exposed to very high vibrations. In the past, we had to replace about one third of our batteries because mechanical damage. Therefore, we needed more efficient batteries with an extended lifetime and reliability”, recalls Krystof Leporowski, Senior Service Technician at Poland-based Elkor Transport. “We have been testing AGM technology for more than two years. This battery is much more robust, it provides additional energy to the truck and allows for lower discharging during parking.”