How to use hand-held battery tester correctly

The right parameters are the key

1) Technology

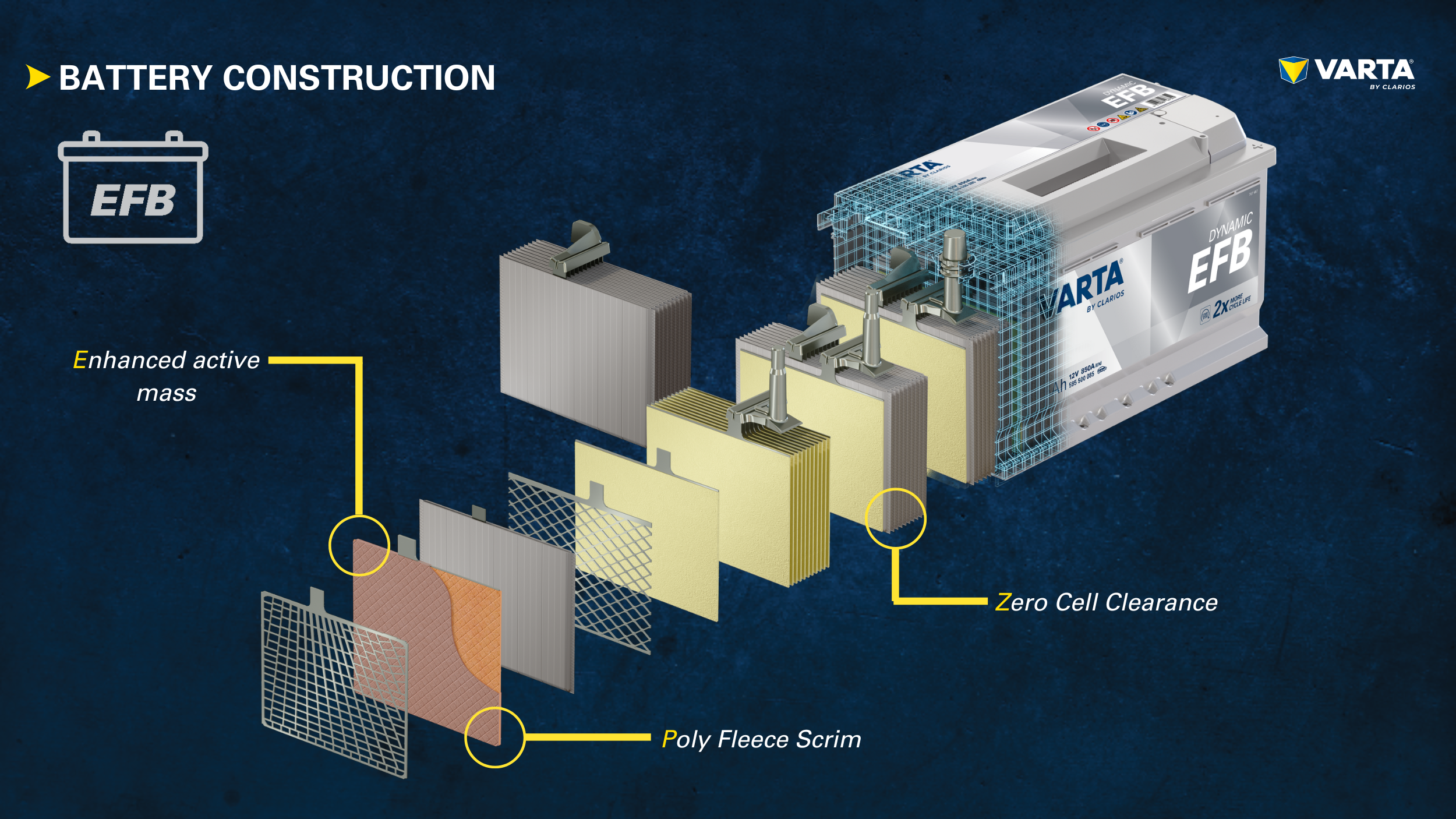

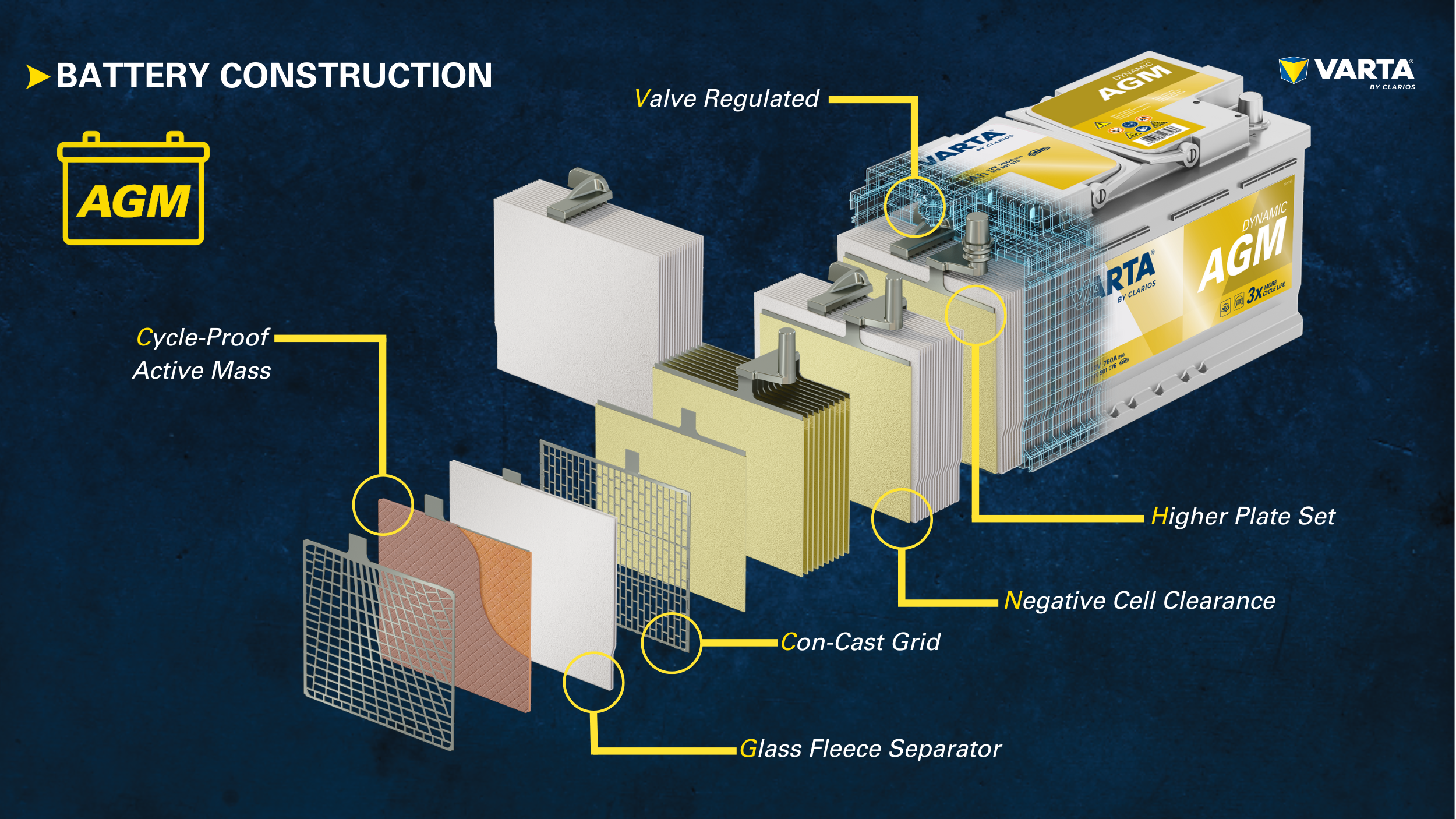

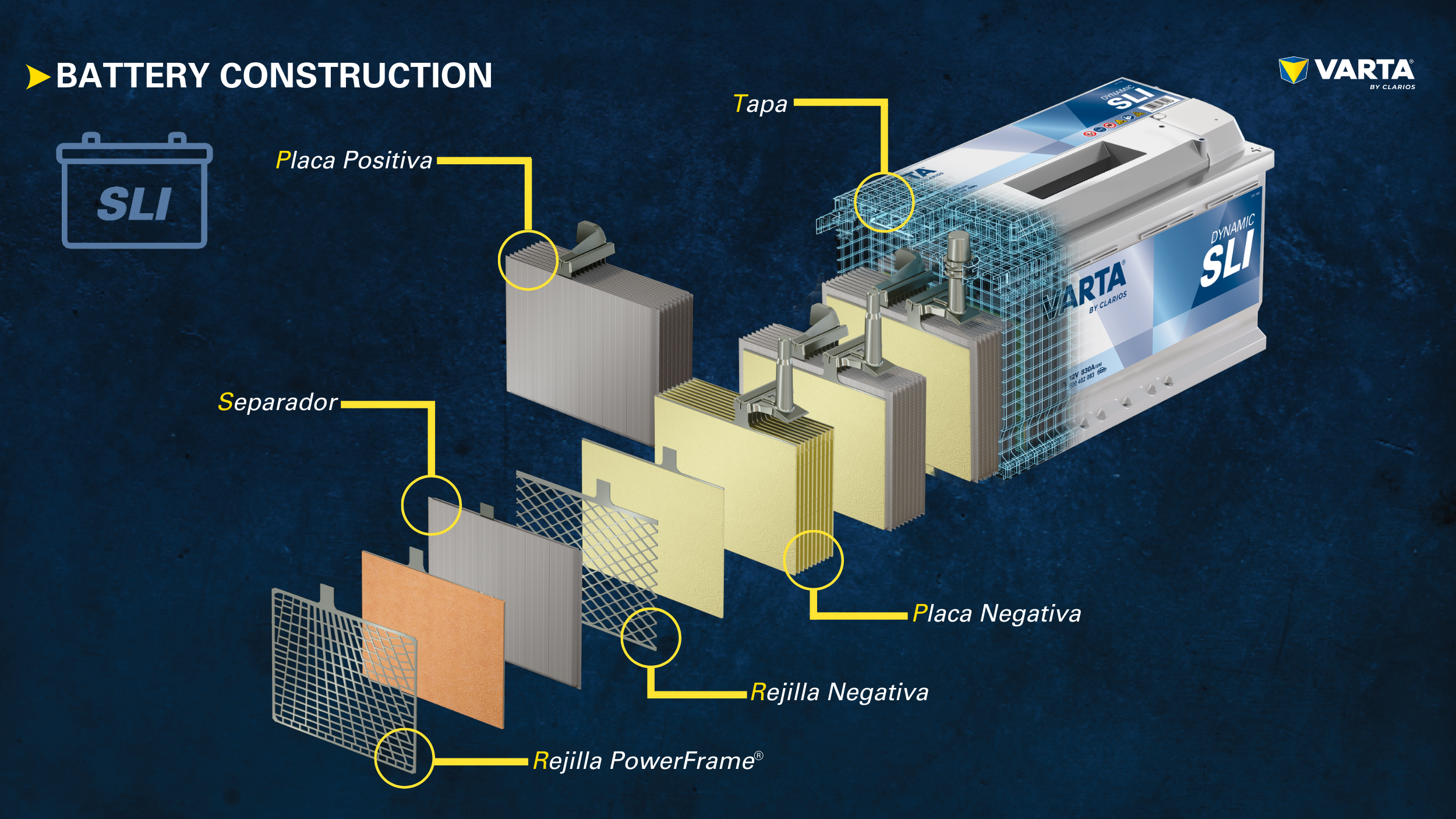

The design of an AGM battery differs in detail quite clearly from a flooded battery. But also between a conventional starter battery (SLI) and an enhanced flooded battery (EFB) there are some differences to improve the cycle life of the EFB.

A closer look inside the battery helps to understand how the battery technology influences the internal structure of the battery.

Examples of differences in design between the battery technologies

| AGM | EFB | SLI | |

| Positive Grid | Powerframe | Powerframe | Powerframe |

| Negative Grid | Con-Cast | Expanded | Expanded |

| Mass Recipe | Most advanced for ST/ST | Improved for ST/ST | Designed for Starting Applications |

| Scrim on pos. Plate | No | Yes | No |

| Separator | Glass Mat | Polyester | Polyester |

| Acid System | Absorbed | Flooded | Flooded |

| Cell Compression | High | Medium | Low |

To understand how the internal structure of the battery influences the test result, it helps to understand how a handheld battery tester works. In very simplified form, a test works by sending a short energy pulse into the battery and then analysing the battery's response to this short pulse to determine its state of health (SOH) and to calculate the remaining starting power.

Thus, no real cold cranking current is measured, but an algorithm is used to derive the battery condition. In order for the tester's algorithm to interpret the battery's response correctly, it is therefore essential that the correct technology is selected before the test..

2) The Test-Standard

A lab test like we perform to prove the cold cranking performance is fundamentally different from the test procedure of a handheld battery tester. The small "(EN)" on the label indicates that we perform the cold start test as defined in the European battery standard EN50342-1

To do this, the battery is first cooled down to a temperature of -18°C in a climate chamber for at least 24 hours. This is already a clear difference to the test in the workshop.

The second major difference is the test procedure itself. In the laboratory test, a real cold start is simulated and it is checked whether the battery can actually deliver the current indicated on the label. Several hundred amps flow for over a minute.

Nowadays, EN 50342 is the standard for car batteries in Europe, but in other regions of the world there are different test procedures. This is especially interesting for the daily workshop routine if you have vehicles from Asian or US-American manufacturers in your workshop and want to change the batteries there. If the CCA rating on the installed batteries was determined according to JIS or SAE standards, the numerical value is not comparable with a value according to EN. In this case you have to select the valid standard in the tester, otherwise you will get wrong results..

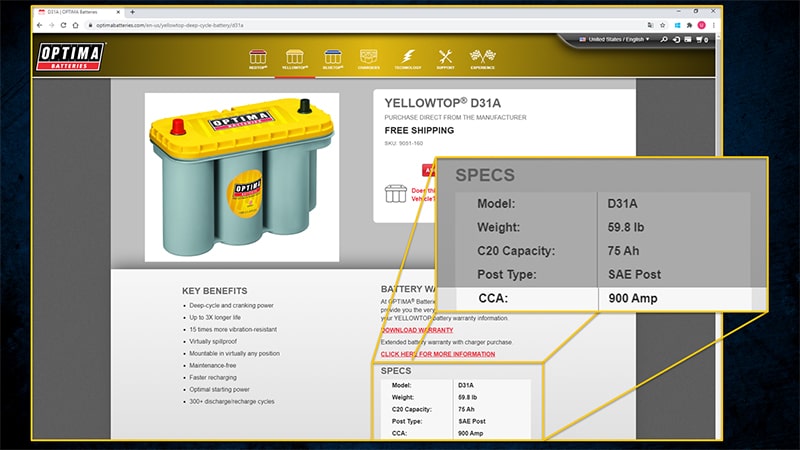

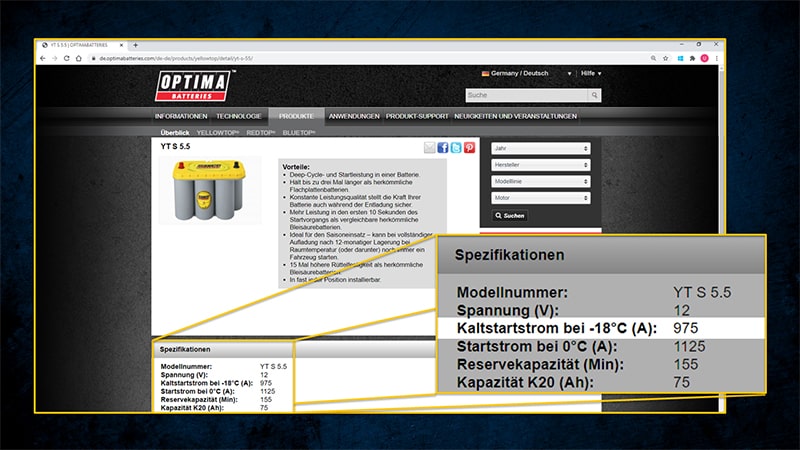

To illustrate how different the numerical values can only be due to a different test procedure with identical batteries, let's compare the cold start values of an OPTIMA battery - also a CLARIOS brand and also a battery in AGM technology. Once tested to EN and once tested to SAE. Remember, it's the same battery.

The difference between "DIN" and "EN"

Most testers offer both "EN" and "DIN" when selecting the test standard. As already described, EN 50342 is the leading standard in Europe today. However, the standardisation process means that the European Standards EN are becoming national standards, so that an EN 50342 becomes a DIN EN 50342.So why do most testers offer both and does it actually not mean the same thing?

.png?sfvrsn=c05a7db9_1)

To make a long story short: In the context of the battery tester, the selection items "DIN" and "EN" describe two different test procedures.

The selection point "DIN" refers to the (no longer common) procedure according to DIN 72311 or DIN 43539-2 for determining the cold start current.

The selection point "EN" refers to the test procedure according to EN 50342-1 which is common in Europe today.

The pure numerical value of a test according to "DIN" is only about 60% of the numerical value of a test according to "EN". In order to obtain a correct test result, it is therefore very important to select the correct test standard.

3)Cold Cranking Amps

The third important entry refers to the actual cold cranking current of the battery. Here it is obviously also important to enter the correct value to get a reliable test result.

With the correct entry of the three parameters for technology, test standard and cold cranking amps, the most important requirements for a correct battery test are given and your customer will get a reliable report about the condition of his battery.

A few more tips for the accurate battery test

In order to get reliable results, it’s crucial to use a battery tester that is able to differentiate between AGM, EFB and SLI batteries.

The capabilities of battery testers are limited. As there are so many different batteries from different manufacturers and with different designs and levels of quality in the market the algorithm of the tester can’t be 100% accurate. On the other hand, the manufacturers of battery testers continually develop and improve the algorithms and devices, therefore it’s recommended to use a tester with the latest technology in order to get the best and most reliable results.

Battery testers are designed to test used and cycled batteries therefore they should not be used to test new batteries e.g. for incoming inspections.

Always connect the battery tester directly to the battery terminals, do not use any other connection or the jumpstart connections. The electrical resistance or capacity of the vehicles system might influence electrical measurements performed by the tester and therefore would lead to biased readings and finally unreliable results.

Conclusion

A test result is only as good as the data the tester is fed with. That is why it is so important to set the battery technology, test standard and CCA rating correctly beforehand. Only then the tester can deliver a reliable result. The test method is fundamentally different from the laboratory tests that we as a manufacturer use in the development and validation of the battery. Therefore a battery test of a handheld tester can never be 100% accurate. Therefore it is even more important that you as a user in the workshop work precisely to get a solid test result.

Find a trusted workshop

Do you work with batteries?

Deepen your knowledge

-

Construction of VARTA Promotive EFB Truck BatteriesA patented mixing element ensures that acid stratification cannot occur in our ProMotive EFB battery. Read our article now to find out exactly how this works and what advantages it brings.

-

The importance of charge acceptance of truck batteriesBatteries with high starting current (CAA) and sufficient capacity (C20) guarantee reliable fleet operation. We tell you why.

-

Battery tips for the leisure seasonGet ready for your journey. Discover helpful tips and tricks for your leisure battery to get the best start to the season

Got a question?

-

Make use of our VARTA Battery Finder to find the battery product that fits your vehicle.

-

43,22% (ADAC Pannenstatistik 2022: https://www.adac.de/rund-ums-fahrzeug/unfall-schaden-panne/adac-pannenstatistik/) of all vehicle breakdowns are caused by battery issues - make sure to eliminate those.

Find a trusted VARTA® Partner near you and get your vehicle battery checked!

-

VARTA team to provide content