The temperature's effect on batteries

What happens to the battery during summer?

It is an experience that most drivers have had: They get into their car, turn the key and nothing happens. Diagnosis: a flat battery. But contrary to popular belief, it is not the cold that stopped the battery from working, it was the hot summer temperatures over the previous years.

Main causes of battery failures

Battery failure has two main causes: wear and tear and the ageing process. Wear and tear is easy to understand when looking at car tyres: the more you drive and the harder your driving style is, the faster the wear and tear. This is similar with the battery: The more often and the deeper car batteries are discharged, and the more electric consumers drain the battery, the higher the wear and tear. Also, if you only use your car rarely or mostly for short distances, the alternator cannot fully charge the battery, while electrical consumers continue to discharge it.

This can be countered with the right battery technology. For example, if you have a vehicle with start-stop function, an AGM or EFB technology is definitely required. A conventional SLI (Starter, Lights, Ignition) battery is not designed for these applications and therefore wear out quite quickly.

The power of an AGM battery can also benefit cars without a start-stop system: AGM technology offers higher power reserves, from which conventional vehicles without start-stop benefit in the form of longer battery life. An AGM battery can also cope with extreme outside temperatures whereas a conventional starter battery reacts to extreme cold and heat with a rapid drop in capacity and discharges more quickly. This was shown in a field study in Dubai, where vehicles with a start-stop system and equipped with conventional batteries all failed after 5 to 6 months while a comparison fleet equipped with AGM batteries remained mobile until the end of the test after 12 months.

It is not possible to make blanket statements about service life and the ageing process, as service life depends on factors such as battery type, ambient temperature, number of cycles, depth of discharge or frequency of use. Nevertheless, wear and tear ultimately affects the ageing process and thus the service life of the battery.

Summer heat furthers the ageing process

Drivers believe that the cold harms a battery, but it is actually heat which causes failure. An outside temperature of +20 °C is optimal for a car battery. But in the summer, the temperature frequently climbs to above +30 °C. High temperatures lead to self-discharge of the battery, which causes the battery to age. This process goes unnoticed in summer and autumn, but when the engine needs more energy to start in winter, difficulties often occur.

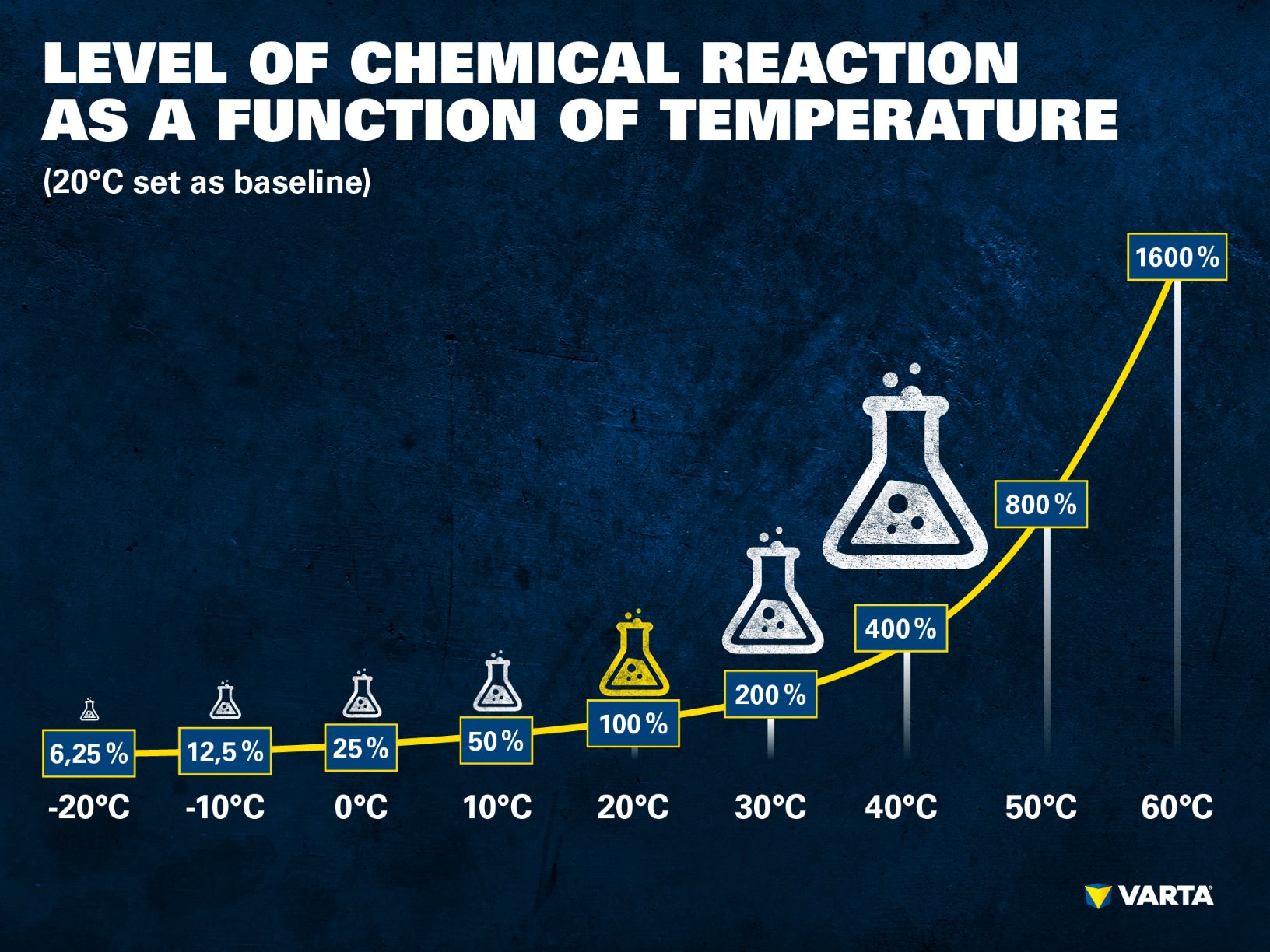

As a rule of thumb, the chemical reactivity doubles for every 10 °C of temperature increase. This causes an exponential rise in chemical reactivity and therefore more damaging factors such as grid corrosion. Just like rust in body panels, grid corrosion also leads to decomposition of the lead alloy inside the battery. As the grid facilitates current conduction within the electrode and forms the mechanical skeleton for the active mass, these two tasks of the grid are performed increasingly poorly which is why high temperatures in summer accelerate ageing and damage the battery.

Why most battery changes are in winter

We have learned that summer heat causes damage to the battery and that higher temperatures increase the level of chemical reaction. This is true for temperatures above 20 °C. If temperatures drop below 20 °C, the chemistry inside the battery slows down. Taking 20 °C as optimum, the chemical reaction at 10 °C drops to 50% and at freezing point it is as low as 25%. This means that the performance of the battery can be perfect in the summer at 20 °C, while in the winter nothing happens at 0 °C and the battery needs to be replaced.

Be prepared for the winter – have your battery checked

Battery tests help to detect battery failures in advance. Ideally drivers should therefore have their batteries checked at a workshop at least once a year before winter. This ensures your mobility and protects you from additional costs and unexpected breakdowns. After all, nothing causes more trouble than a battery that still provides enough power for the lights but is too weak to start the engine.

Find a trusted workshop

Do you work with batteries?

Deepen your knowledge

-

Construction of VARTA Promotive EFB Truck BatteriesA patented mixing element ensures that acid stratification cannot occur in our ProMotive EFB battery. Read our article now to find out exactly how this works and what advantages it brings.

-

The importance of charge acceptance of truck batteriesBatteries with high starting current (CAA) and sufficient capacity (C20) guarantee reliable fleet operation. We tell you why.

-

Battery tips for the leisure seasonGet ready for your journey. Discover helpful tips and tricks for your leisure battery to get the best start to the season

Got a question?

-

Make use of our VARTA Battery Finder to find the battery product that fits your vehicle.

-

VARTA team to provide content

-

VARTA team to provide content