How summer heat affects battery

The automobile clubs drive most of the battery-related services during the first frost and during the first cold winter days. You get into the car, turn the ignition key and then nothing happens for a while. Diagnosis: Battery flat. The diagnosis is correct in the vast majority of cases. However, you should know that it was not the first cold night that knocked the battery out, but mainly the hot summers before.

This is why a battery ages

When a battery reaches the end of its service life, it is a combination of various degrees of wear and aging. Wear and tear and calendrical aging are two different effects which can be explained very vividly by looking at car tyres.

Wear occurs when a vehicle is on the road. The driving style, i.e. the way the tyre is used, also has an influence on wear. Calendar aging, on the other hand, also occurs when the vehicle is not moved or the tyre is simply in stock. Here too, the material becomes brittle at some point and the tyre ages.

Just as the driving style influences wear, the external environmental conditions influence calendar ageing.

For a tire this is quite obvious. What this means for the battery will be briefly explained in the following.

Wear and tear of the battery:

Wear is caused by the use of the battery. If the battery is used frequently and extensively, it will wear out faster than a battery that is used infrequently and rarely.

Against the common assumption, it is not so much the number of engine starts that causes the battery to wear out, it is rather the number of charge and discharge cycles (Cycle Life) and the depth of these cycles (Depth of Discharge).

Wear and tear can be countered with the right battery technology. For example, if your customer has a vehicle with start-stop function, an AGM or EFB technology is certainly required. A conventional SLI battery is not designed for these applications and therefore wears out quite quickly.

Calendrical aging of the battery:

For a battery in a classic car, which is rarely used and is parked most of the time, wear and tear is usually not a great deal. In this case, the effect of calendrical aging is more likely to become apparent.

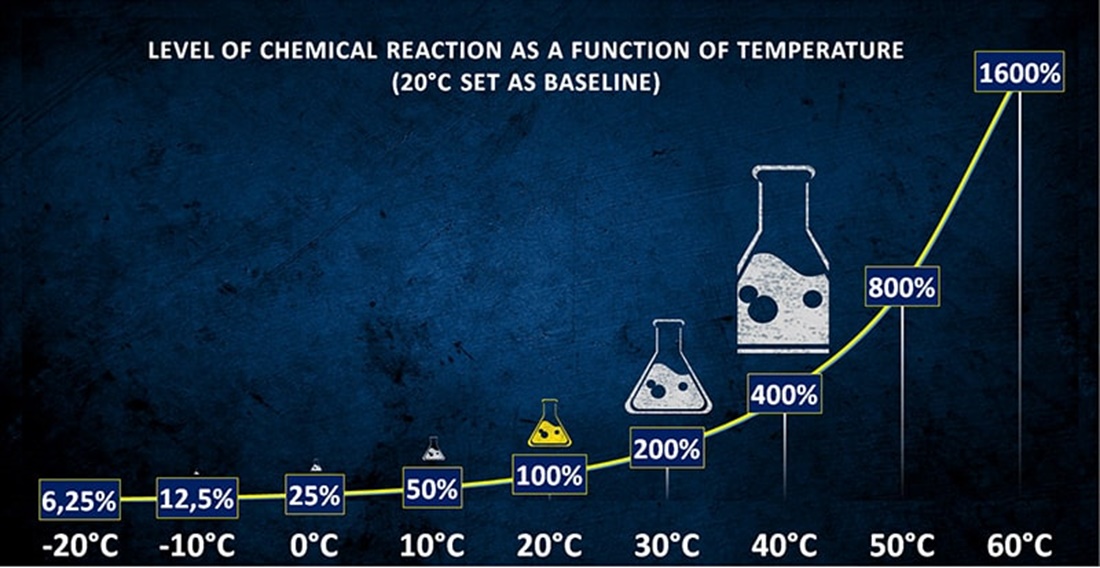

In order to explain the effects of calendrical aging, we would have to delve into the depths of the chemistry of the lead-acid battery here. But that would be taking things much too far at this point. That is why we limit this topic to one important factor: temperature. The chemical processes in the battery are strongly dependent on temperature.

As a rule of thumb you can say that the chemical reactivity doubles for every 10 Kelvin temperature increase. This leads to an exponential increase in reactivity. In fact, this effect is used to speed up laboratory tests by performing them at high temperatures. Not only in our battery lab, but actually with all suppliers and OEMs.

And here we come back to the beginning of this article, namely that the high temperatures in summer accelerate the calendrical aging and damage the battery.

Grid corrosion shortens battery life

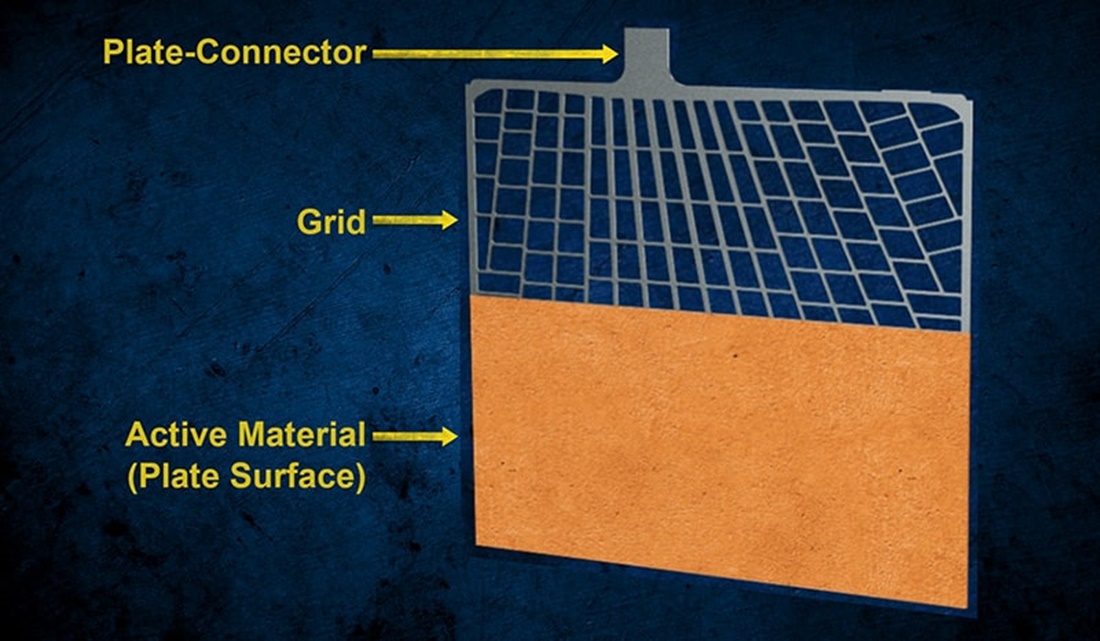

The grid inside of the battery fulfils two essential functions for the proper operation of the battery. Firstly, it conducts the current flow from the plate surface to the plate connectors. And second, the plate provides the carrying structure for the active mass of the plate.

One of the most important aspects when it comes to temperature induced ageing is the so-called grid corrosion. Just like rust in body panels, grid corrosion also leads to decomposition of the lead alloy.

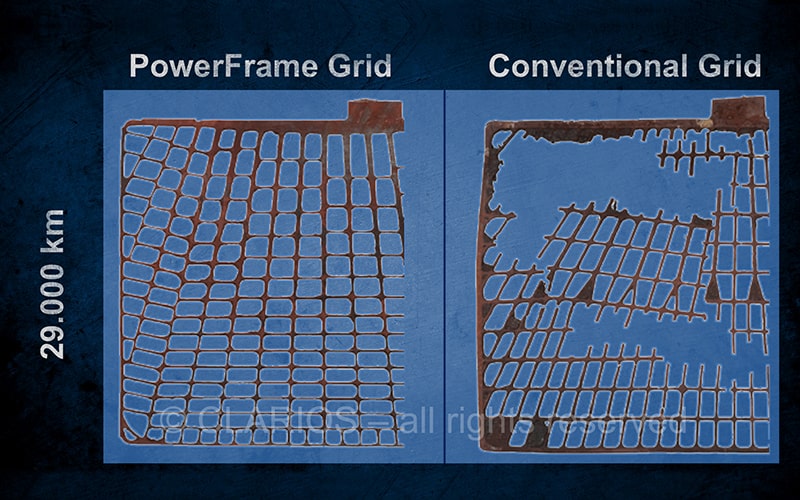

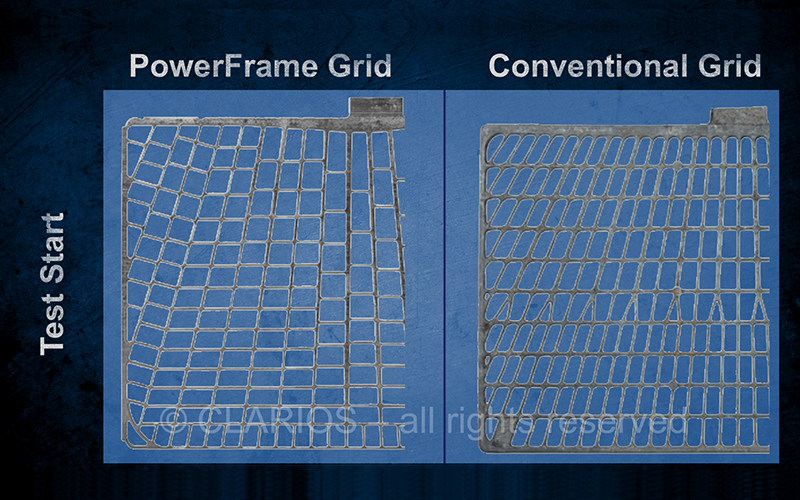

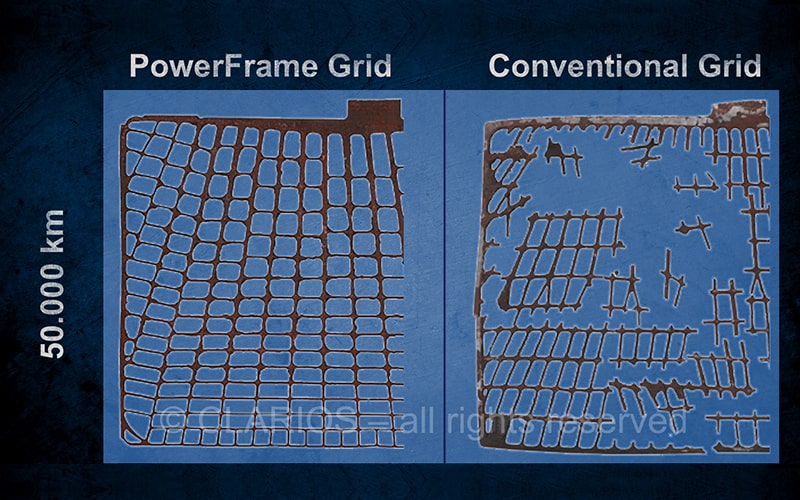

The illustrations below show original pictures of grids from a field test conducted by our US colleagues in Las Vegas. The climate in Las Vegas is a desert climate, with long, hot summers and thus ideally suited for a field test aimed at aging.

These pictures show very clearly what grid corrosion is all about and also why our VARTA PowerFrame grid is one of the key factors for long battery life.

The grid has two tasks, as mentioned above. It facilitates current conduction within the electrode and forms the mechanical skeleton for the active mass. That both are getting worse and worse with increasing grid corrosion is very evident.

Grid corrosion shortens battery life

We know now that it is the hot temperatures in summer that causes damage to the battery. Nevertheless, the statistics show very clearly that most battery failures occur in winter. How is this related? Also in this case the temperature is again very important.

As already touched on the subject of aging, the reactivity of the chemistry inside the battery strongly depends on the temperature. If we read the curve (link auf das Bild “graph influence of temperature.png” weiter oben im Artikel einfügen) the other way round, we see that the lower the temperature, the slower the chemistry inside the battery becomes. This means that on a winter day, the battery cannot give the same performance as on a warm summer day. And so it is possible that the car still starts smoothly at 20°C, but nothing happens at 0°C.

“Batteries die in summer, but it's only in winter that we realize we've bet on a dead horse.”

U. Germann – CLARIOS Technical Training Manager

We test that your customers stay on the road

As you know, with VARTA you get "The Original", meaning batteries in OEM quality. As a partner to OEMs, we are constantly developing and testing our batteries to ensure that we always offer the best product. The tests are not limited to laboratory tests, but we also regularly accompany field tests. Only in this way can we test our batteries in "real life" and in interaction with the complete vehicle electrical system.

Just recently, we completed a 12-month field test with one of our OEM customers. Similar to our PowerFrame test in Las Vegas, we went into the desert and came to Dubai.

In this test we equipped a taxi fleet with different batteries. Since a liter of gasoline costs only about 40 cents in Dubai, Start-Stop does not yet play a major role there. However, the hot climate and the excessive operation of the taxis causes the batteries to fail after only a few months. In a nutshell, the ideal test conditions for a field test.

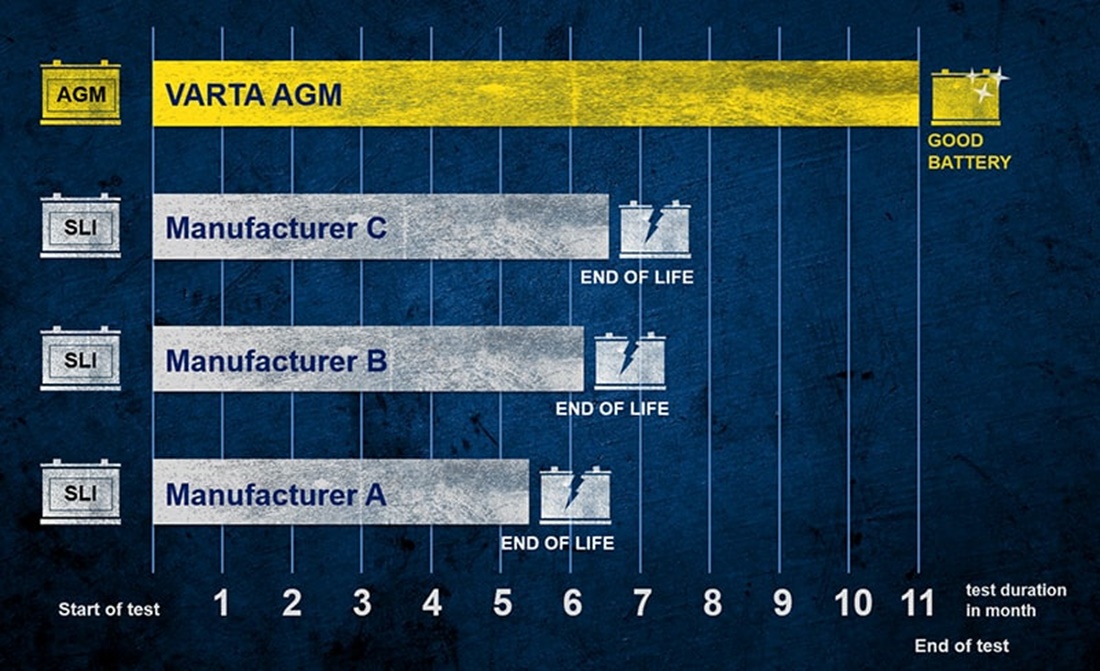

Since the vehicles had no Start-Stop function on board, all vehicles were equipped with conventional SLI batteries from different manufacturers. For comparison, we have equipped a number of vehicles with VARTA AGM to show that the AGM technology also offers many advantages outside Start-Stop.

A total of 60 identical vehicles were equipped with the different batteries and data loggers. The result: Without exception, all SLI batteries failed after about 5-6 months. The comparison fleet equipped with AGM batteries remained mobile until the end of the test without any battery replacement.

Test key facts

Vehicle usage statistic

- 19 hours average time of driving per day

- 14,000 km driven per month

- 300 engine cranks per month

Battery usage statistic

- In 80% of operation the battery temperature was above 60°C. Maximum temperature was up to 75°C

- All returned AGM batteries had good remaining capacity of more than 75% of the initial value.

“This test conducted in close cooperation with one of our OE partners shows once again how superior modern AGM technology is when it comes to battery life and performance.”

M. Hoh – CLARIOS Senior Manager Vehicle Expertise

Conclusion

After reading this article, we now know that it is the hot temperatures in summer that causes damage to the battery.

When a battery reaches the end of its service life, it is a combination of various degrees of wear and aging.

Wear is caused by the use of the battery. If the battery is used frequently and extensively, it will wear out faster than a battery that is used infrequently and rarely.

Calendrical ageing is very much influenced by temperature, since the chemical effects, including unwanted side effects, are strongly dependent on temperature. One of the most important aspects when it comes to temperature induced ageing is the so-called grid corrosion which leads to decomposition of the lead alloy.

As the grid has two tasks, first to facilitate current conduction within the plate and second being the mechanical skeleton for the active mass. Both are getting worse with increasing grid corrosion. Our field tests under hot climate conditions have once again proven that AGM technology has been proven to give you peace of mind, whether in a vehicle with or without a start-stop function.

Batteries die in summer, but only in winter we realize that the battery has its best days past. Therefore we recommend to test every battery when a vehicle comes to your workshop. In this way you can inform your customers at an early stage about an upcoming battery failure and recommend a preventive replacement.

Find a trusted workshop

Do you work with batteries?

Deepen your knowledge

-

Construction of VARTA Promotive EFB Truck BatteriesA patented mixing element ensures that acid stratification cannot occur in our ProMotive EFB battery. Read our article now to find out exactly how this works and what advantages it brings.

-

The importance of charge acceptance of truck batteriesBatteries with high starting current (CAA) and sufficient capacity (C20) guarantee reliable fleet operation. We tell you why.

-

Battery tips for the leisure seasonGet ready for your journey. Discover helpful tips and tricks for your leisure battery to get the best start to the season.

Got a question?

-

Make use of our VARTA Battery Finder to find the battery product that fits your vehicle.

-

VARTA team to provide content

-

VARTA team to provide content