-

Deactivating start-stop

Is a regular battery sufficient if start-stop is deactivated?

Start-stop systems as we now know them, have had an eventful history. Start-stop systems as we now know them, have had an eventful history. More than 40 years ago, Toyota developers presented an electronic system to automatically stop the engine when the vehicle stopped. At the beginning of the 1980’s Volkswagen made initial attempts in this direction – in those days with a button to switch off the engine when required. The result: The Golf III Ecomatic was the first vehicle from the Wolfsburg car manufacturer to be equipped with a start stop function.

Today, start-stop is standard equipment

Nowadays, start-stop is no longer a gadget in the list of options, instead it’s standard equipment for most vehicles. The reasons for this are more stringent legal emission limits and a change in environmental awareness on the part of consumers.

New fuel saving functions support start-stop

The fuel saving systems in modern vehicles have developed much further in comparison with those in the early days. With additional functions such as recuperation (recovery of braking energy) they go far beyond simply switching off the engine at red traffic lights.

As fuel saving technologies became increasingly common for vehicle manufacturers over the years, the more intelligent they became. Among other things this has meant that the battery and energy management of the entire vehicle have become increasingly merged.

Can I install a conventional battery if I permanently deactivate the start-stop system?

As has already been said, these days switching off the engine when the vehicle is stopped is only one of many fuel saving functions.

In addition to recuperation, these also include sailing (the engine switches off while driving) and boosting (more rapid acceleration for short periods). The battery therefore also has a heavier load than in conventional vehicles, even if the start-stop function is deactivated.

Almost all modern vehicles have a dedicated battery sensor (BMS) to control the efficiency and comfort functions in the vehicle. If the battery is replaced without being correctly registered in the BMS, this can result in increased wear. Many vehicles are also equipped with a so-called self-learning battery sensor. In this case, the manufacturer assumes that the right battery technology is installed. If a conventional battery is installed, this can cause increased battery wear and ultimately premature failure.

Our tip: Decide on the right technology from the start and help the environment! The VARTA Battery Search identifies which battery is best for the particular vehicle.

-

The right battery for short distances

Which is the right battery for short distance driving?

The problem: The battery is put under a disproportionate strain due to starting processes and also has to provide the power for electrical consumers. Over short distances very little time is available to fully recharge the battery. This becomes especially critical if the battery already shows signs of wear due to intensive use or insufficient charging.

Old starter batteries show their weaknesses on short trips.

The age of the battery also plays a role. Over the years, batteries lose capacity and their internal resistance increases. This results in a deterioration of charge acceptance. With a large number of short trips, the charging balance tips into the negative range, so that the battery loses more energy than it can accept from the alternator. This is especially critical in the winter months when more power is needed to start the engine and many electrical consumers such as lights, rear window heating, seat heating and fans are in operation while driving. Eventually, a conventional car battery can no longer deliver enough power for a cold start and lets the driver down.

The essential thing is the charging balance.

Even with a driving profile that contains a large number of short trips, balanced charging is relevant for a good state of charge of the battery. Because of this, in any case of doubt, drivers who mainly travel short distances should choose a battery which is too powerful rather than one which is not powerful enough. Although a powerful battery does not affect the charge balance or charge behavior, it gives the driver greater reserves until the battery can be recharged over a longer distance. The power which is used to start the vehicle should at least be recharged during the journey. For short distances this is best achieved if power-hungry components are not used. The alternator can then feed more power into the battery during the short driving period to compensate for the previous loss of charge. Even if the vehicle is parked for a long period, such as during holiday time, some control devices drain the battery and cause a gradual discharge.

An AGM battery gives a feeling of security for short trips.

For short trips the low internal resistance of an AGM battery over its entire life is a definite advantage. With this type of battery the acid is bound in a glass mat, so no acid layering occurs and there is no damage to the active material. The resulting long-term charge acceptance is essential for a positive charge balance and a long battery life.

An AGM battery can also be operated in a partially charged state without a negative effect on battery life. The large reserves of an AGM battery ensure reliability and mobility for short trips.

-

AGM batteries vs. gel batteries

Gel battery or AGM battery? These are the differences

What are the differences and what do the batteries have in common? Both types of battery are VRLA batteries and are equipped with a vent valve. The abbreviation VRLA stands for Valve Regulated Lead Acid Battery. With this closed battery type the hydrogen which is generated by the battery is recombined, so that topping up with distilled water as with wet batteries is not required. Apart from these common features, there are significant differences between gel batteries and AGM batteries.

Gel batteries

A gel battery has a similar structure to a conventional wet battery. The positive and negative electrodes are surrounded by an electrolyte. However, as the name suggests, the electrolyte is not in liquid form but rather is in the form of a gel due to the addition of silica. This provides greater resistance to vibration and the inclination of the vehicle. The encapsulated design facilitates handling and improves safety. If the battery is in an intact state, the user does not need to be afraid of leaking fluid. Therefore, in the trade, gel batteries are often referred to as maintenance free batteries.

AGM batteries

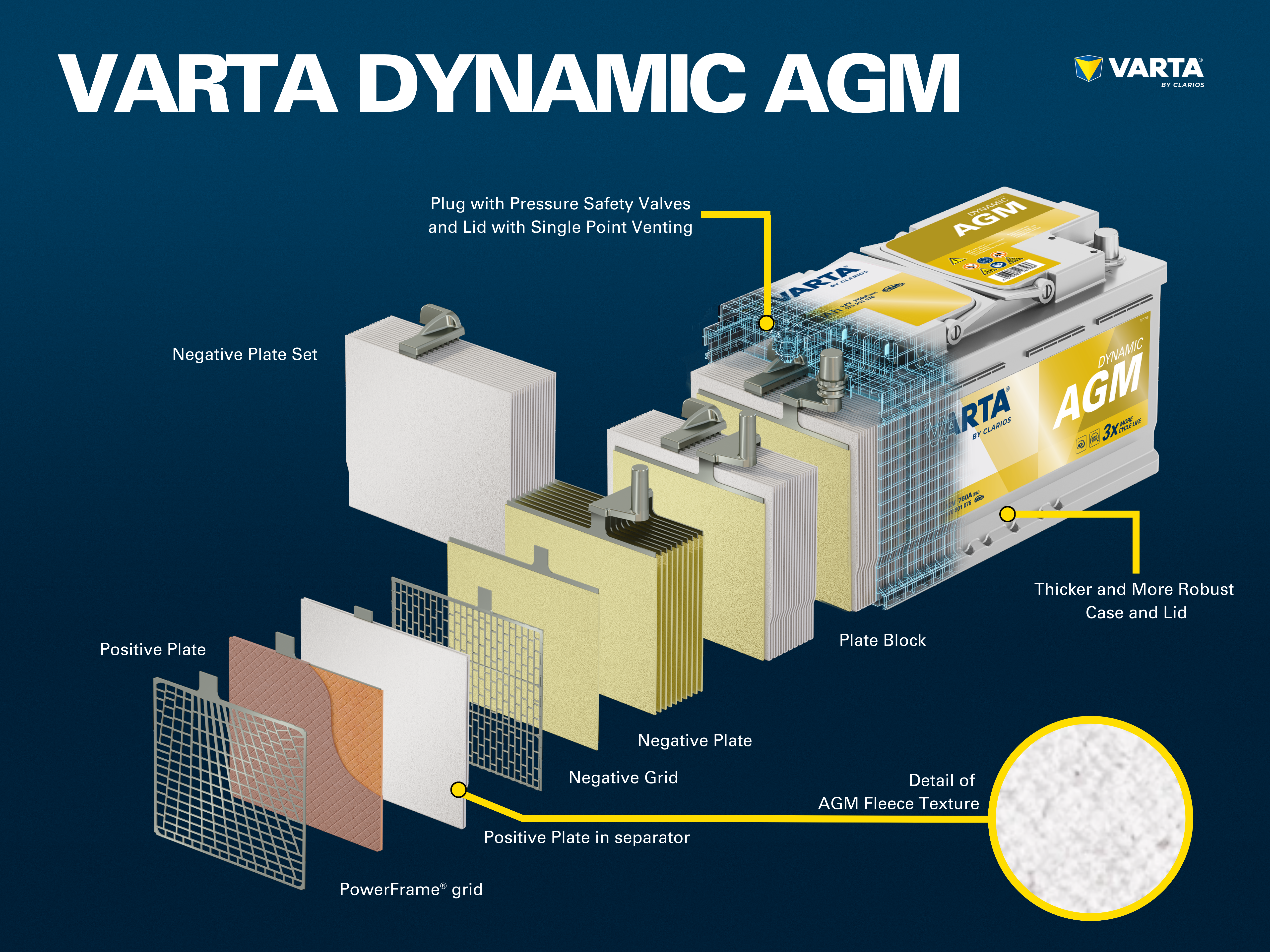

The abbreviation AGM stands for Absorbent Glass Mat. In an AGM battery, the electrolyte is completely bound in a glass fiber mat. AGM batteries are leak-proof and can also deal with inclined positions without problems. This, and their resistance to vibrations are the reasons why AGM batteries are especially favored for off-road and motorcycle use. In comparison with conventional starter batteries, AGM batteries can withstand three times as many charging cycles. The increased performance which is achieved by the structural features, is one of the main arguments for the use of an AGM battery. Long life, excellent performance and greater safety make AGM batteries the premium batteries for modern vehicles.

Comparison of the characteristics of gel batteries and AGM batteries

Gel batteries score highly with their low electrode wear, which results in a longer service life in comparison with conventional lead-acid batteries. However, due to their increased internal resistance gel batteries cannot produce high cold start currents within short intervals. A second disadvantage is their susceptibility to temperature fluctuations.

AGM batteries have been specifically designed for vehicles with automatic start-stop systems and increased power demands. AGM batteries are recommended for all drivers who operate a large number of electrical devices and driver assistant features or who simply require greater starting and supply reliability through an extremely high performance battery. The positive features of AGM batteries include:

- Leak-proofing

- Position tolerance

- Vibration resistance

- Greater Safety

Even if the casing is damaged or broken, the acid remains bound in the glass mat. An uncontrolled escape of battery acid can therefore be largely ruled out.

When is it worth buying an AGM battery?

The high, constant cold start current makes an AGM battery the right choice for vehicles with start-stop technology and recovery of braking energy. Even vehicles with simple automatic start-stop systems and increased power requirements benefit from an AGM battery. The large number of charging cycles increases the service life and therefore cost-effectiveness. Conventional gel batteries are designed for use as supply batteries, but not as starter batteries and certainly not for cars with automatic start-stop systems or vehicles with a large number of electrical consumers. AGM batteries are the modern answer to the need for more dependable energy, environmental compatibility and reliability. -

These devices drain the battery

Electrical consumers in cars – how much power do they use?

Various kinds of devices and driver assistant features consume power and put a strain on the battery. Constant use of these electrical consumers on board makes driving more economical. A consumption of 100 Watt corresponds to a fuel consumption of 0.1 l per 100 km. Drivers can do without comfort features if they want to save the battery. However, safety assistants and functions (e.g. Lane Assist) should remain in operation even with a low charge level. The reduction of load on the battery is no way proportional to the damage which results from an accident due to failure to utilize maximum safety.

Safety is more important

Heated windscreens and rear windows ensure a clear view in winter. Their power consumption is about 120 watts. Windscreen wipers ensure a clear view of traffic. Depending on the wiper speed with is set, windscreen wipers use between 80 and 150 watts. Vehicle lights are essential for safety in the dark and should be switched on in good time in the darker winter months. Modern driving lights equipped with LEDs can manage with as little as 50 watts.

Power for driving comfort

The heater obtains its energy from the engine via a heat exchanger. The interior ventilation transports the heat to the passengers and consumes 170 watts at a medium setting. In winter, seat heaters are a welcome comfort function. This functions purely electrically and consumes 100-200 watts. Smart systems control seat heaters economically and occasionally switch them off to safe energy. Air conditioning can now be found in all modern cars. In summer it provides cooling and in winter it prevents steamed-up windows better than the interior fan. Air conditioning systems mainly obtain their energy from the engine, however they also put an additional load of 500 watts on the battery.

Assistants and connections

An electric sun roof is an essential feature for lovers of fresh air. To open and close the sun roof, the motor requires 200 watts. Power windows and central locking systems are controlled by servo motors which need 150 watts. However, they are only used for a few seconds. The case is different with the cigarette lighter which is often used as a plug socket to charge smartphones or operate other devices. However, with a power consumption of 50 watts, the demands on the battery are modest.

Electrical units and control devices

The starter motor is the most energy-hungry consumer in the car, but without it nothing works. Multiple starting attempts drain the battery, especially if it is old and has been poorly maintained. The radiator fan starts when the engine gets too hot, for example in traffic queues in summer when there is no airflow. The fan takes 800 watts out of the battery. In modern vehicles, the engine controller regulates and monitors important engine functions. Engine management improves the efficiency and environmental compatibility of the entire drive system – with a power consumption of up to 200 watts. Some cars have headlight cleaning systems to clean the headlights. With the use of conventional H7 lights, more than 100 watts are needed for the entire vehicle lighting.

AGM batteries – A power station for modern cars

The number of electrical consumers in cars is continually increasing. Because of this, when going for a service or tire change, drivers should have the battery checked by the workshop. With a high performance battery enough power is available in summer and winter to start the engine and supply all of the electrical consumers. A modern AGM battery provides the greatest power reserves and protection against unexpected breakdowns. They can withstand heavy demands and can withstand three times more charging cycles than a conventional battery. -

Testing the battery - Step-by-step

Car battery testing instructions

According to the latest studies by the German Automobile Club ADAC, in 2022 about 46% of breakdowns were due to the battery. The reasons for this include the increased electrification of vehicles. These days, greater demands are made on the battery – up to 150 electrical consumers and the automatic start-stop system in modern cars require sufficient power. A regular battery check by a specialist workshop is therefore advisable in order to detect an imminent battery failure before a final breakdown occurs.

Correct testing of the battery state by specialist workshops

Basic principles:

Testing of a conventional wet cell battery:

A measuring device which can only measure the state of charge of the battery is suitable to test a conventional car battery. In an ideal case, an open circuit voltage of about 12.8 V is measured with a Multimeter. If the voltage falls below 12.4 V, the battery should be recharged as soon as possible. A continuous low charge damages the battery due to sulfation.

As the main load on a conventional starter battery is due to the starting process and after charging by the generator there is no further discharge, the cold start current is decisive in this case. Due to aging and wear the capacity of the battery to deliver high currents gradually decreases. In addition, the lower the charge (determined by measuring the open circuit voltage), the lower the possible current which can be delivered during the starting process.

Testing a start-stop battery:

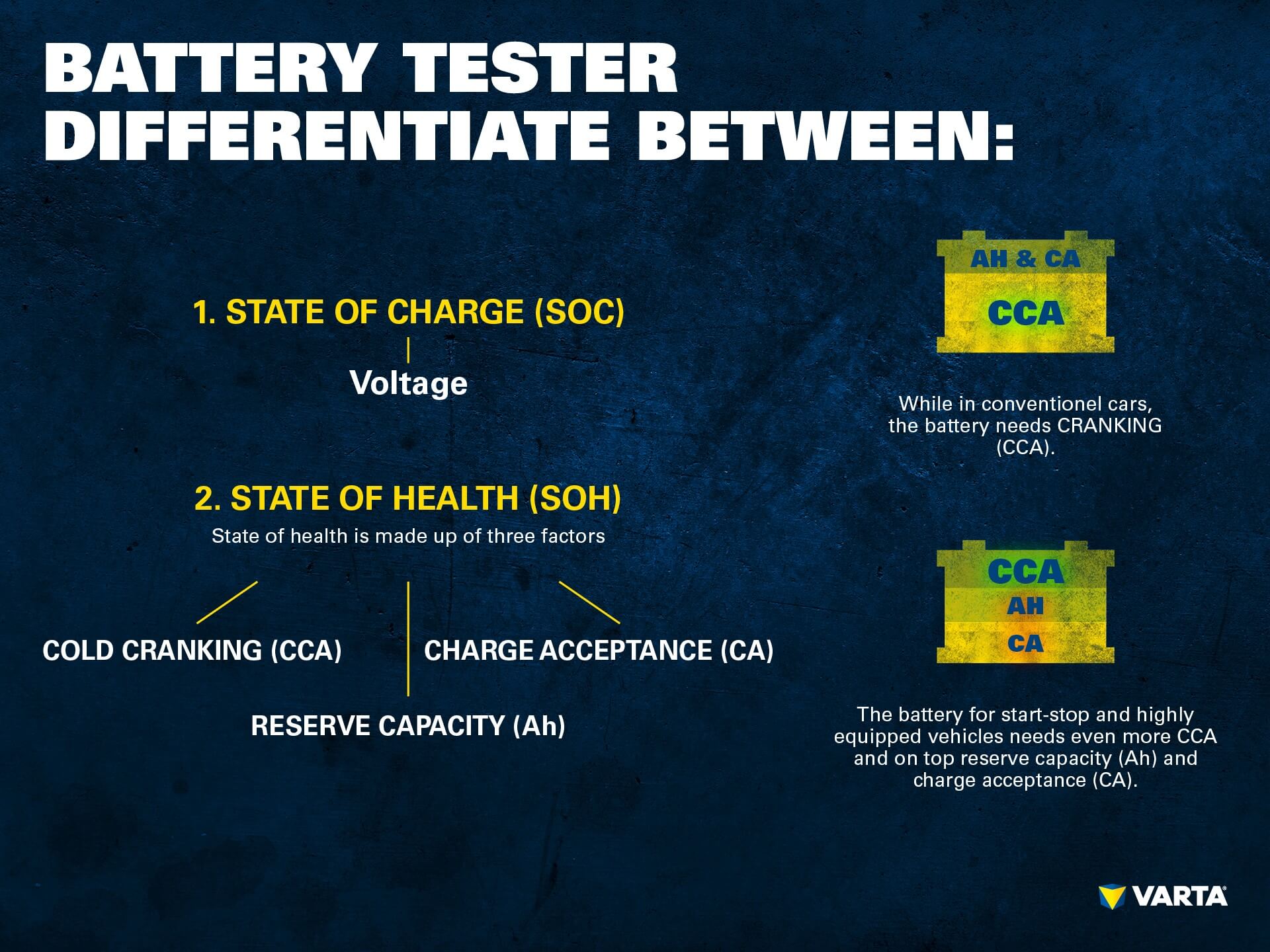

When testing a start-stop battery, not only the state of charge (also known as the “SOC”), but also the state of health (“SOH”) of the battery are important.

While the SOC can be simply determined with a voltage measurement, a complex test procedure is required to test the SOH, in order to make a reliable statement about the state of the battery. Among other things, the determination of the SOH takes into account the cold start capability (CCA), the residual capacity (Ah) and the charge acceptance (CA).

Just as vehicle technology has continued to develop over the years, batteries with new technologies such as AGM or EFB have also developed further. To obtain reliable test results, especially with regard to the SOH, it is essential to use modern test devices which are adapted for the new battery technologies.

Battery testing step-by-step:

(Please note the information from the manufacturer of the device.)

- Connect the battery tester to the battery terminals to determine the state of charge and the internal resistance. In principle: Connect the red cable to the positive terminal and the black cable to the negative terminal. The sequence for connection and disconnection does not matter.

To connect the testing device to a battery which is located in the trunk or the passenger compartment, the battery terminals there and not the starting aid contacts in the engine compartment must be used, as the resistance of the cable which is installed in the vehicle would affect the measurement. - To connect the testing device to a battery which is located in the trunk or the passenger compartment. Connect to the battery terminals on the battery and not the starting aid contacts in the engine compartment, as the resistance of the cable which is installed in the vehicle will affect the measurement.

- Set the battery tester to the correct battery type: Starter battery, gel battery, EFB or AGM battery. The device uses a different test algorithm for each battery type, so that an incorrect setting would produce an incorrect measurement value. In addition, for some test devices it is important to know whether the test is being made on a battery installed in the vehicle, or whether it is outside of the vehicle.

- Enter the stated cold start current for the battery into the device, including the measurement method which is used. Common standards are DIN, EN, IEC, JIS and SAE. Details of the testing standard can be found after the details of the cold start current on the battery label.

- The testing device then carries out the test automatically and provides the result.

Correct interpretation of test results? How to do it!

By the way…

To obtain correct results when measuring the conductivity, a consumer such as the headlight should be switched on shortly before the measurement. This removes any surface tension before the measurement.

Battery Testing Guide (PDF Download)

- Connect the battery tester to the battery terminals to determine the state of charge and the internal resistance. In principle: Connect the red cable to the positive terminal and the black cable to the negative terminal. The sequence for connection and disconnection does not matter.

-

Changing a start-stop battery

How do I change an EFB or AGM battery?

Replacement of modern batteries is now considerably more complex than it was 20 years ago with conventional wet batteries. Up to 28 different steps are now necessary. This is just one of the reasons why replacement should be carried out by a specialist workshop. We have summarized the most important points below.

Where is the battery anyway?

The answer to this question used to be very simple: under the hood of course. Now things are completely different. If you open the hood of a modern car, you will often not find the battery. These days, only 58% of batteries are in the engine compartment. 40% are in the trunk and 2% are installed in the passenger compartment. For some models, seats may even need to be removed or carpets cut in order to access the battery. An extra airbag qualification is necessary to remove the seats, for which special training is required. This is another reason to have the replacement carried out by professionals.

Many steps and more time for battery changes

In a car with Start-stop technology the battery must only be replaced with a type which has been approved by the car manufacturer and which meet all of the necessary requirements. Due to the more complex on-board network, replacing a start-stop battery takes longer than for a conventional starter battery in a simple vehicle.

Replacing a modern start-stop battery takes up to 28 steps – which greatly increases the time which is required.

Linked on-board electronics

A start-stop battery is a part of the on-board electronics and is linked to the vehicle electronics via the Battery Management System (BMS) and the battery sensor (EBS). The control unit detects the number of starts and the energy flow, monitors the state of charge and controls charging. When a start-stop battery is replaced, the energy management system is programmed by the diagnostic device in the workshop.

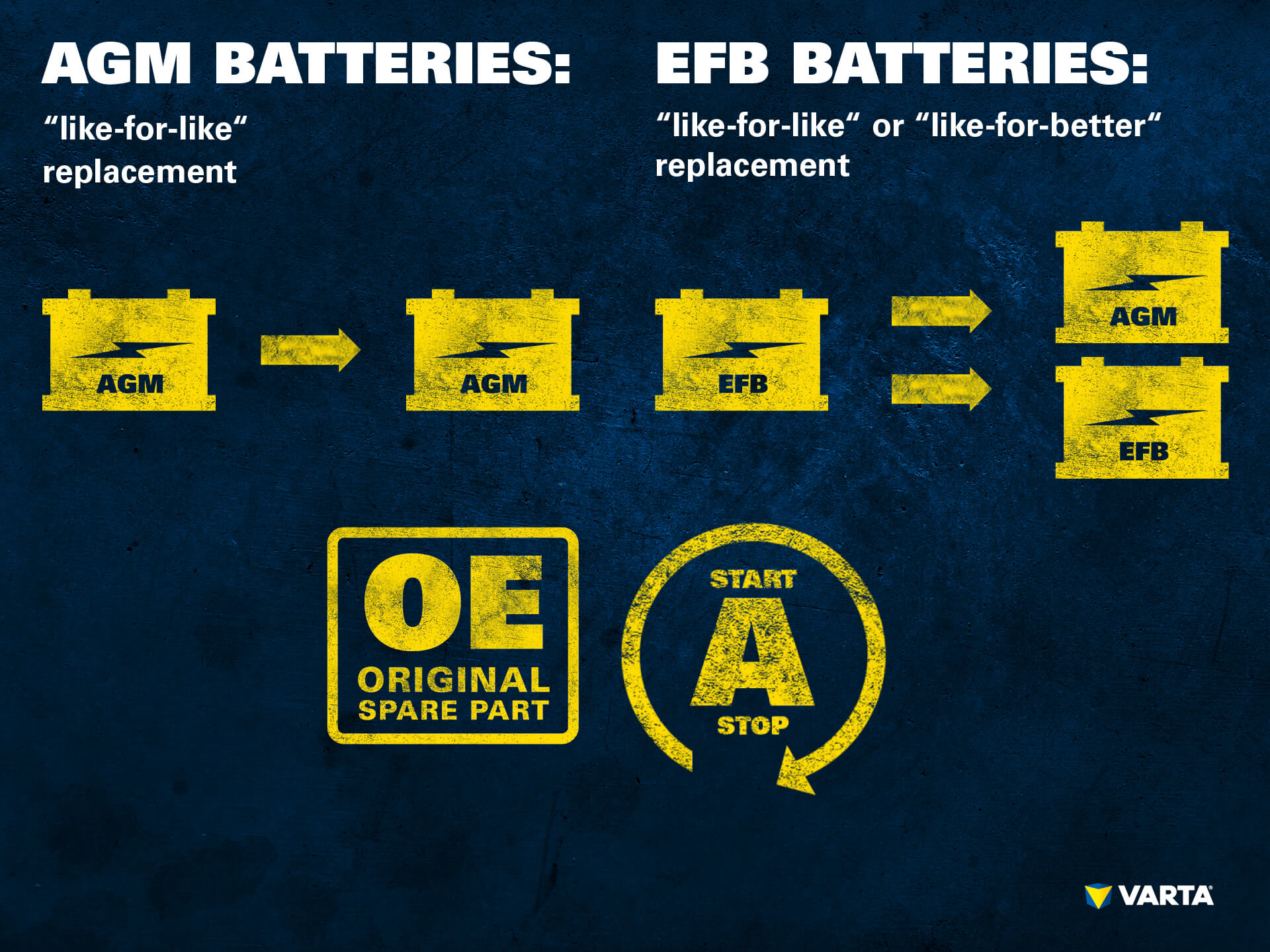

Incorrect DIY replacement of a start-stop battery can cause malfunctions. A battery replacement which is not carried out correctly can cause restriction or even failure of the start-stop function, which can result in increased fuel consumption and restriction of the comfort functions. The experts in a workshop have been trained to handle current battery technology and are familiar with battery replacements. They also know that an AGM must always be replaced with an AGM and an EFB must at be replaced with an EFB or an AGM.

Replacement without loss of data

When an EFB or AGM is replaced, a specialist workshop takes a series of points into account, which guarantee that the battery functions properly later on. Because the car is temporarily without power during the battery replacement, important operating settings must be noted beforehand. Alternatively, a second battery can be connected to maintain the operating voltage.

Error messages and malfunctions after battery replacement

After the new battery has been installed and connected, the automatic start-stop system may not function for several hours. In this case, the workshop will inform the driver of this and give them the appropriate instructions. Drivers should contact the workshop directly in case of any malfunctions or error messages which occur after a start-stop battery has been replaced. In most cases, these are temporary and are due to incomplete data processing. In some cases, the vehicle requires genuine driving data to complete the setup. Some vehicle control units have a self-learning function, so that some of the error messages disappear automatically. In the VARTA Partner Portal workshops can find details of the procedures for replacing the battery for an automatic start-stop system, as well as the time which is required and which batteries are available as replacements.

-

EFB and AGM

Battery types for automatic start-stop systems

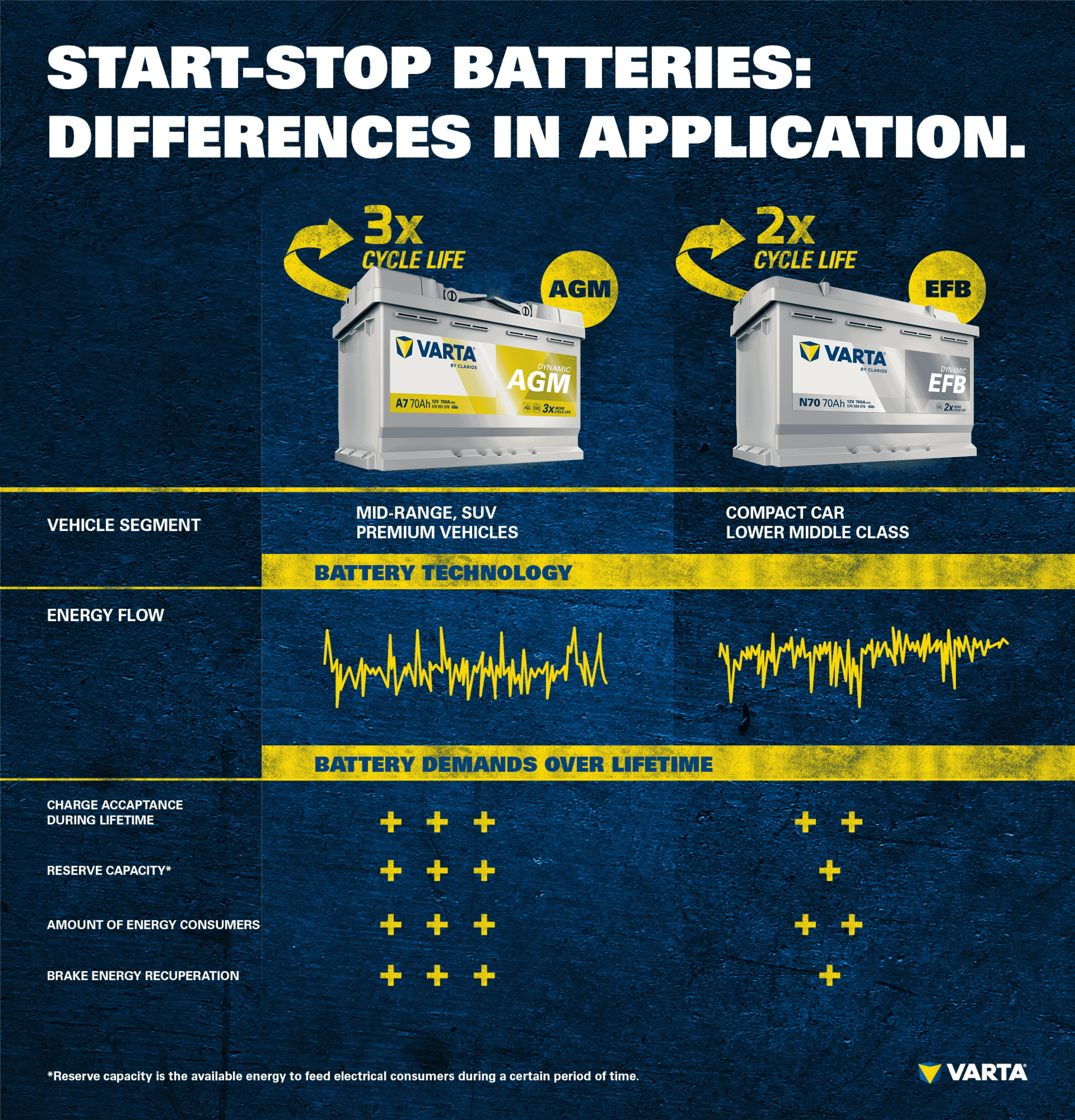

In cars with an automatic start-stop system, the battery is subjected to greater demands. One of the reasons is the high charge throughput. In addition there are a large number of electrical consumers such as steering wheel heating, air conditioning system and safety functions, which have to be reliably supplied with power even while waiting at traffic lights with the engine stopped. The only batteries which can withstand the challenges of automatic start-stop systems are EFB batteries and AGM batteries.

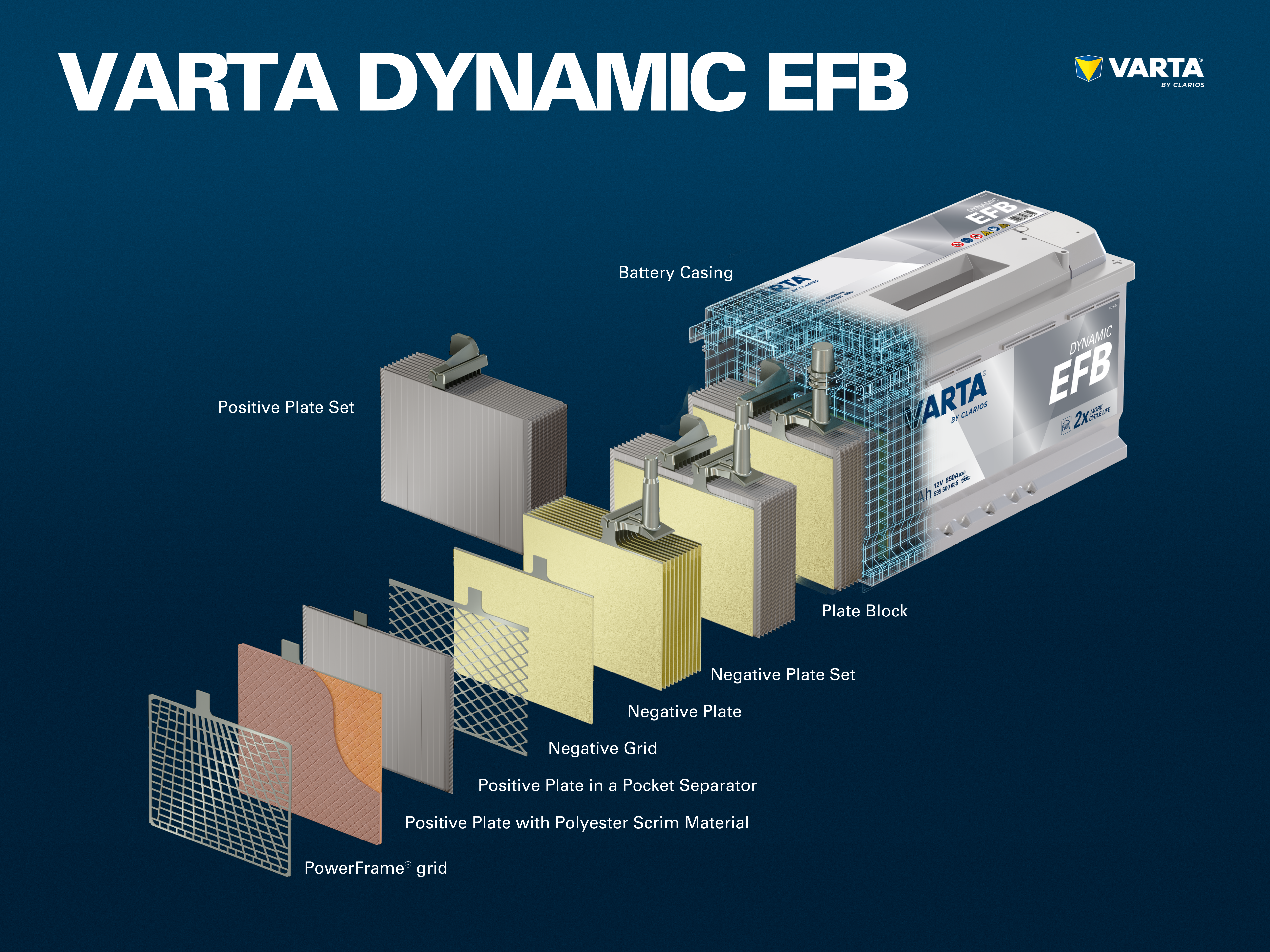

EFB batteries – for compact and mid-range cars with start-stop

EFB batteries are suitable for the power supply of cars:

- with simple automatic start-stop systems

- vehicles without start-stop with demanding driving requirements (e.g. in urban traffic),

- for cars with extensive equipment but without automatic start-stop systems.

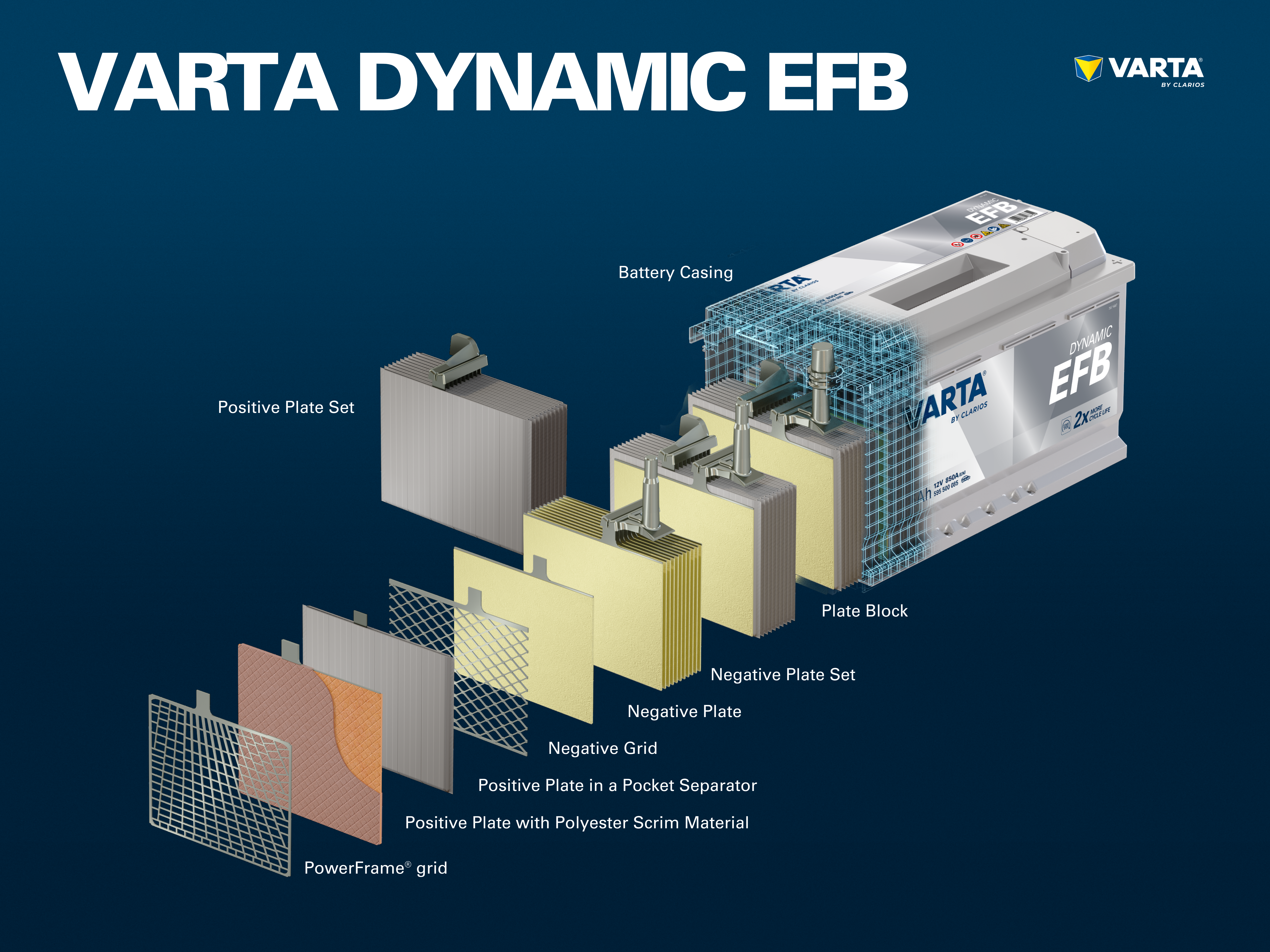

The design of EFB batteries is a further development of conventional lead-acid batteries. A Polyvlies material on the surface of the positive plate helps to stabilize the active material of the plates and extend the life of the battery. The separators in the cells of EFB batteries have a low resistance and optimize the charging process. EFB batteries have good cycle stability and load capacity. According to the EN test they can withstand twice as many charging cycles compared to conventional starter batteries.

AGM batteries, for upper mid-range cars, SUVs and premium cars

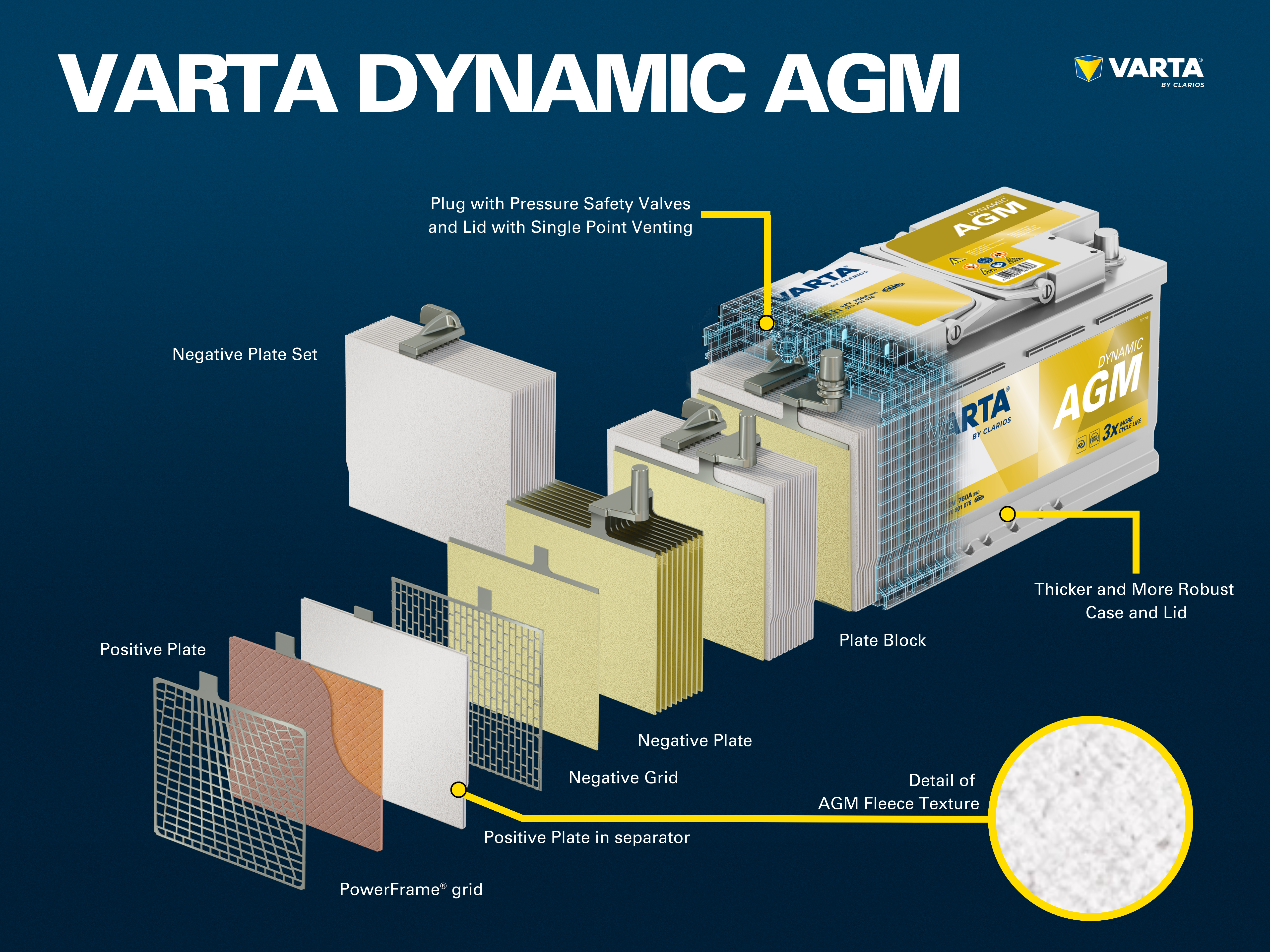

AGM batteries are ideal for vehicles with automatic start-stop systems with braking energy recovery (recuperation), or for cars with premium equipment and sophisticated accessories, as a conventional starter battery cannot handle the high power demands of these systems.

The electrolyte in an AGM battery (AGM stands for “Absorbent Glass Mat”) is bound in an absorbent glass fleece. This makes the battery maintenance-free and leak-proof. Even if the battery casing is fractured, battery acid cannot escape. An AGM also has excellent cold-start characteristics. They powerfully start the starter motor and reduce its running time. Thanks to the cycle stability of the battery, a warm engine can be switched off and started again several times at short intervals, without the risk of difficulties when restarting. With regard to their service life, AGM batteries also have significant advantages over simple starter batteries. They can withstand three times more charging cycles* than a conventional starter battery.

Recuperation with AGM batteries

Every braking phase is actually a waste of energy. With braking energy recovery (recuperation) the energy which results from braking is not completely lost. Depending on driving conditions, part of the energy which is recovered from the braking process is fed into the battery of the vehicle. The prerequisite for this is a battery which is suitable for recuperation: AGM batteries provide this technology.

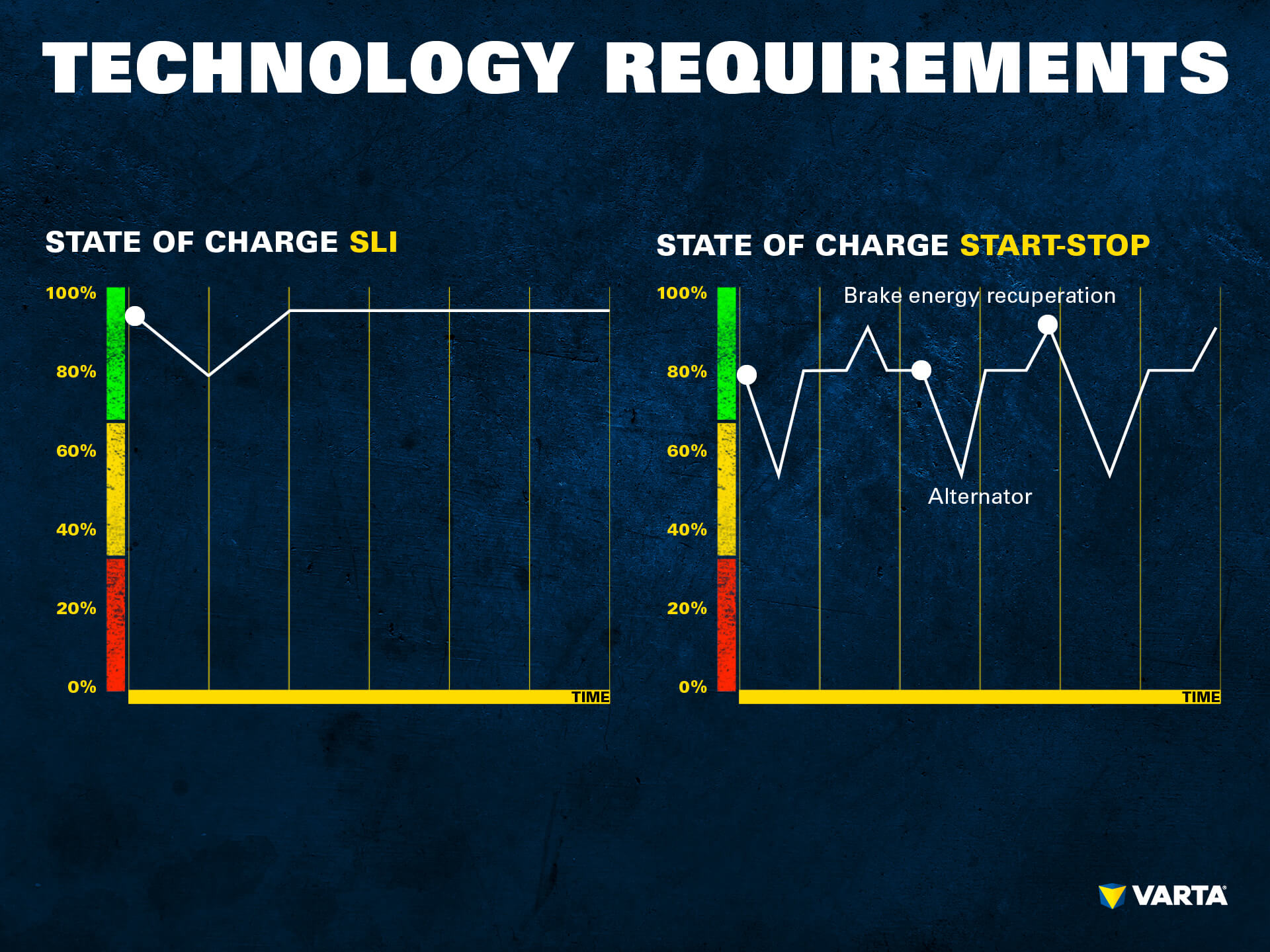

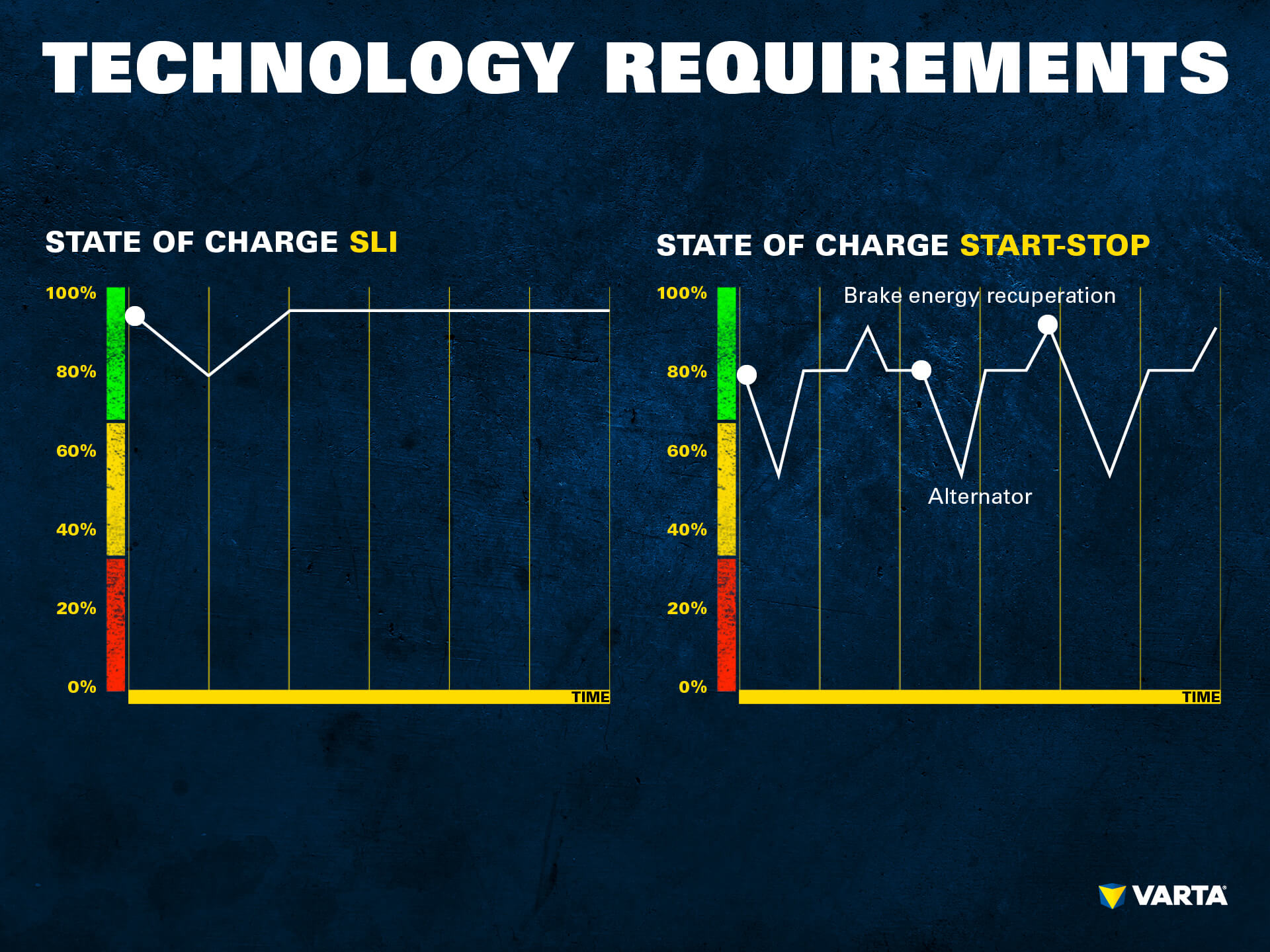

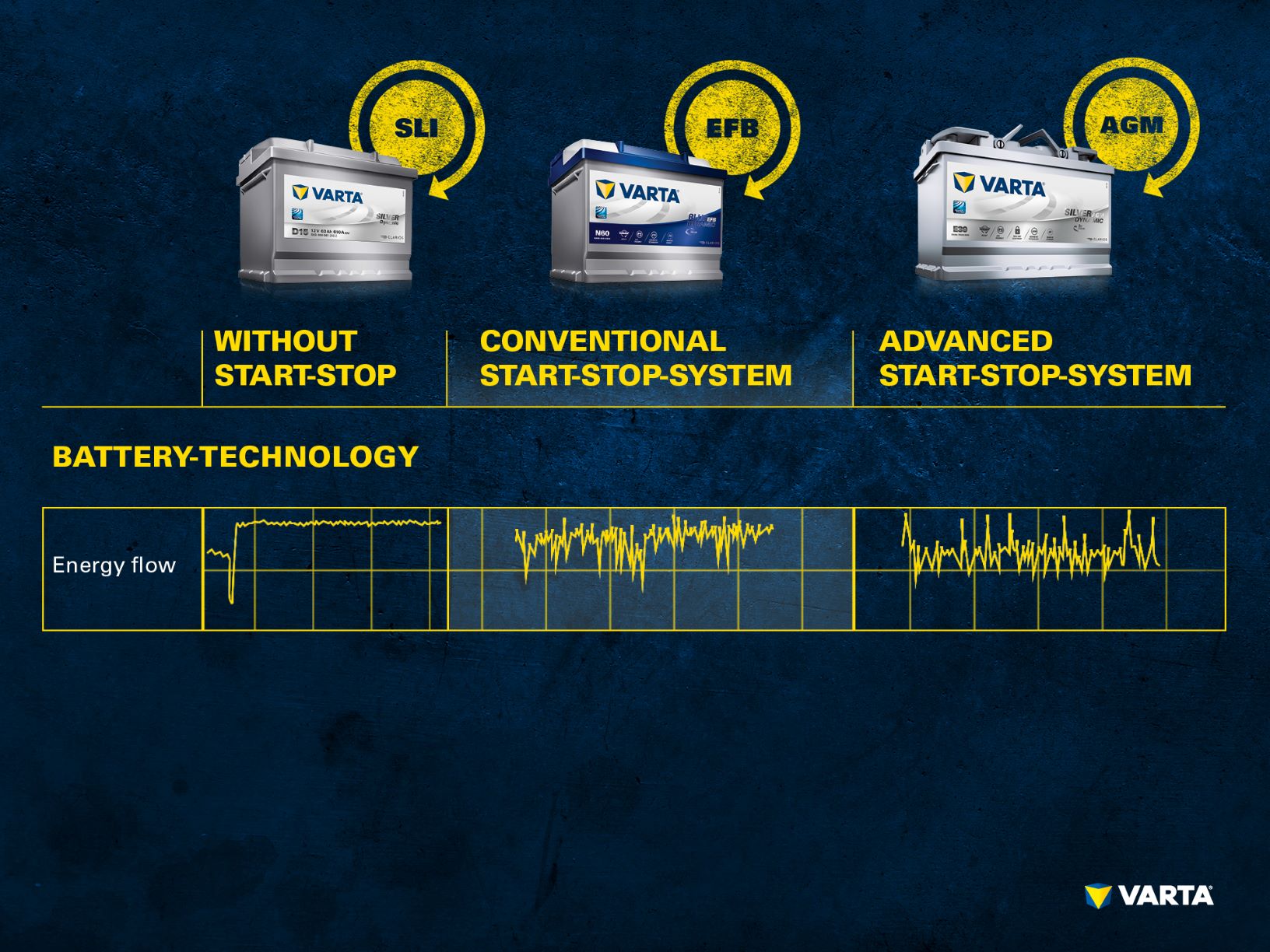

A conventional wet battery (SLI) only starts the engine once per journey. The optimum 100% charge of an SLI only reduces once when starting and is then recharged by the alternator during the journey (see the diagram on the left).

With an automatic start-stop system, the battery has to start the engine several times during the journey. The charge level of the battery therefore falls several times and also, electrical consumers still need to be supplied with power during the standstill period. This puts an especially large load on the battery. During driving, the battery is recharged, just like a conventional starter battery. However, due to the recovery of braking energy, additional charge capacity must be available in order to be able to feed in the regenerative braking energy. AGM batteries are therefore operated in the partial charge range and only attain a full 100% charge during recuperation (illustration on the right). In the subsequent stop phase, the charge reduced due to the supply of electrical consumers, so that there is once again sufficient “room” available to store the energy from the next braking phase.

Because of this, batteries for automatic start-stop systems are subjected to various states of charge within a short time. Discharge when starting the engine and charging by the alternator and recuperation cause considerably greater loads, which over long periods can only be reliably withstood by an AGM battery.

In combination with the vehicle’s energy management system, AGM batteries ensure a reliable and constant supply of the electrical consumers in the vehicle, while also ensuring optimum efficiency.

*Test standard EN 50342-1 and for EFB and AGM, additionally EN 50342-6

-

Consequences of the wrong battery

Consequences of fitting the wrong battery for start-stop systems

Start-stop technology is a sophisticated technology, which enables cost savings for drivers and importantly environmental benefits. However, the benefits of the start-stop technology involve an increased load on the battery. Start-stop can switch off the engine at every time the car comes to a stop and start it again when the accelerator is pressed or the brake released.

When Start- Stop is active, say waiting at traffic lights, the large number of electrical consumers still have to be supplied with electricity. The radio is on, a smartphone is being charged, and the air conditioning continuously provides the necessary cooling in the car. In spite of this, the engine must still be started by the battery when the traffic light turns green. To meet these requirements, innovative batteries have been developed especially for use in vehicles with automatic start-stop systems. The wrong battery ultimately could lead to unwished consequences.

Consequences of using a conventional car battery

A conventional starter battery cannot meet the demands of a vehicle with an automatic start-stop system. This is true both for cars with simple start-stop systems and EFB batteries as well as for vehicles with advanced start-stop systems. These vehicles which are equipped with recuperation, the electricity which is generated by the braking process is stored in the AGM battery.

These are the possible consequences of using a conventional starter battery in a vehicle with start-stop:

Loss of warranty

The use of unsuitable or unapproved starter batteries in vehicles with start-stop will result in the loss of warranty. The driver or the workshop will be liable for all consequential damage and loss of function associated with the installation of an incorrect battery.

Loss of driving comfort

Ideally, the Battery Management System (BMS) detects the installation of an incorrect battery and adapts the start-stop system to the lower power of the battery in order to ensure that the engine continues to start. In case of doubt, comfort functions such as seat heating and other features are not available during a stop phase.

If the battery management system does not detect the installation of an incorrect battery and does not adjust the energy management accordingly, this can result in a considerable reduction of the service life of the battery.

Restricted start-stop functionality

Due to the incorrect battery the amount of electrical energy is too low which will lead to rapid deterioration of the battery and causes the start-stop system to rarely or even never switch off the engine. This causes increased fuel consumption and greater pollution.

Leaking battery acid

Battery acid may leak if the battery case bursts due to overload and electrochemical processes. A sudden escape of battery acid can cause a severe risk to health.

Use of the incorrect battery technology in a start-stop vehicle results in more rapid deterioration of the battery.

Because of this, as a result of overload, in extreme cases the battery acid may also leak.

Which is the best replacement battery?

In Europe, there are about 30,000 different models of vehicles, so that it is impossible to know which the right replacement battery is for each of these models. The VARTA Partner Portal provides partner workshops with assistance in this decision, with battery positions, battery selections and installation instructions for almost all vehicles which are in use in Europe. For end customers, the VARTA battery search is an ideal tool to find the right battery.

You can read more about this topic in our article on the correct replacement battery for start-stop systems.

However, it is important to remember that an AGM must be installed wherever an AGM was originally installed! This is the only way to ensure that the vehicle functions as well as with the original component after the battery has been replaced.

-

Special start-stop batteries

Why do I need a special battery for the automatic start-stop system?

Every starting process is associated with a large amount of energy from a car battery. The battery must be in a very good condition to reliably supply a high starting current. Especially with modern vehicles with automatic start-stop systems, the engine is switched off several times during the journey. During these phases the battery continues to supply all of the electrical consumers with energy. A conventional starter battery (SLI) is not designed for this charge output (i.e. continuous discharging and charging).

Only a battery with start-stop technology can deal with these demands and withstand the strain.

The generator charges the starter battery while driving

In a car which is not equipped with an automatic start-stop system, the starting process is usually a one-off event. While driving, the generator supplies the electrical consumers such as the entertainment system and navigation device, so that if the generator is working, there is no discharge of the starter battery during the journey.

The start-stop battery has a double load

The case is different for cars with start-stop technology. During a journey through the town, the battery is subjected to a series of start and stop periods. If the car is stationary at traffic lights with the engine stopped, electrical consumers such as lights, windshield wipers, radio or displays still need power. The load is increased by continuous discharge and charging.

In particular, short journeys present a challenge for the battery. Especially with old batteries and in winter, the charge acceptance of the battery reduces, so that adequate recharging during short journeys is not always ensured. This can result in gradual discharge of the battery, so that at some point, the battery no longer has enough energy to start the engine. Due to the special technology, the internal resistance of AGM batteries remains considerably lower than that of conventional batteries over their entire life, so that sufficient charge acceptance is also ensured over a long period and short journeys with many start-stop phases can be handled better by AGM batteries.

Three advantages of AGM batteries

Excellent cold-start characteristics

AGM batteries have a large cold start current. They powerfully start the starter motor and reduce its running time. Thanks to the cycle stability of AGM batteries the engine can be switched off and started again several times at short intervals, without the risk of difficulties when restarting.

Balanced state of charge

With modern vehicles, the AGM battery is not only charged by the generator, but is also fed by the braking energy recovery system. Normal starter batteries must be kept permanently fully charged and can therefore not absorb the energy which is generated by recuperation. AGM batteries can be operated in the partial charge range and therefore provide sufficient “extra” capacity to store the energy which is generated on braking.

High reserve capacity

The high reserve capacity ensures the power supply for all types of electrical components. The cycle stability of AGM technology ensures the power supply to components while also providing a high starting power. Even if the battery is not fully charged, because, for example, electronic assistants and consumers which ensure comfort are supplied during a stop, or the generator has been temporarily decoupled to reduce the load on the engine.

Interesting facts about start-stop technology

Start-stop systems require a battery with modern technology, because normal starter batteries are not designed to meet the higher demands of these vehicles.

The architecture of the electrical system in modern vehicles requires a compatible battery technology in order to function properly and reliably. For this reason, in many vehicles, new batteries must be “registered” – the Battery Management System (BMS) must know what type of battery is installed in the vehicle in order to exploit its full potential. If an incorrect battery is installed in the vehicle or is not correctly registered, this can result in premature battery deterioration and another breakdown.

For this reason, only EFB or AGM batteries should be installed in vehicles with automatic stop-start systems. If an AGM battery is already installed in the vehicle, it must always be replaced with another AGM battery.

-

Start-stop does not work

Reasons why the start-stop system does not work

Start-stop technology makes driving more economical and environmentally friendly. Because of this, by 2020 one in three cars on our roads will be equipped with this technology. For example, if a car stops at traffic lights, the start-stop system switches off the engine. As soon as the clutch pedal is pressed again, or the brake is released in the case of an automatic transmission, the engine starts again immediately.

In addition to frequent engine starts, which the battery must supply for this process, it also supplies all of the electronic consumers even when the engine is switched off. You could say that the car battery is the heart of the system for modern vehicles. It is often assisted by an intelligent Battery Management System (BMS), which is, so to speak, the brain of the car’s electronics. The reason why the start-stop system does not function can be due to the interaction between both of these essential systems.

The battery management switches off the start-stop function

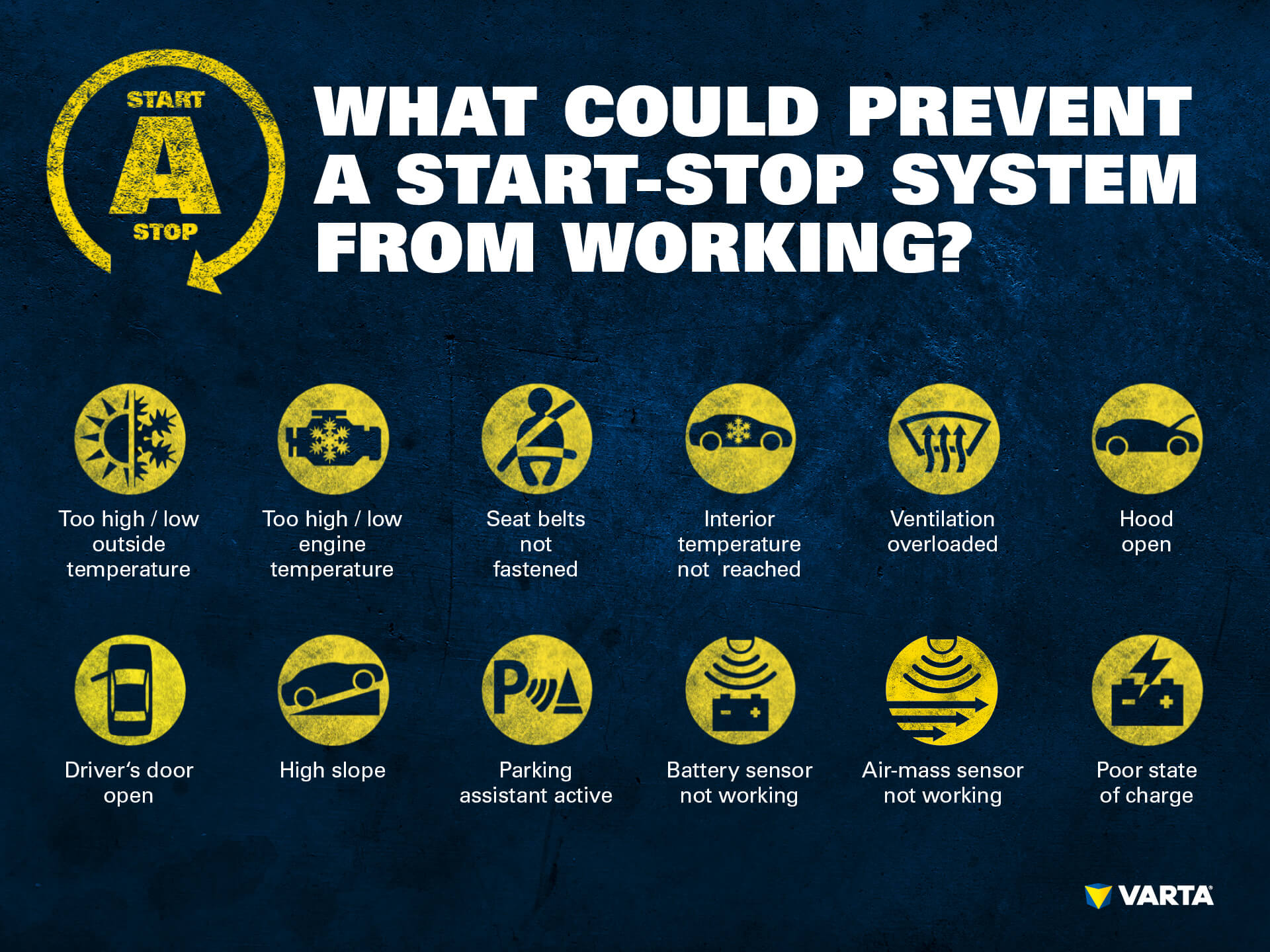

The top priority for any battery is to start the engine. However, if the battery only has a low charge, the Battery Management System (BMS) switches off the start-stop function to enable the engine to be started. A similar protective mechanism operates in the following cases:

The wrong battery technology has been installed, which can only provide a small number of charging cycles.

The outside temperature is too high or too low. If the battery needs too much power to supply the fan, the start-stop function is switched off. When, and whether this happens, depends on the comfort settings by the particular car manufacturer. It may also be the case that the start-stop function is still supported, but the air conditioning system is automatically reduced.

The engine temperature is too high or too low. If the engine is not heated by consumers or by the battery, it must generate its own heat by combustion, which requires a higher starting current. The result: The start-stop function is not activated. If the engine threatens to become too hot, it has to be cooled by the fan on the radiator, because the airstream is not sufficient or does not exist when stopped at traffic lights. The fan requires a large current, so that the start-stop function is not activated.

The wrong battery technology causes problems

A further cause could be that when it was replaced, the battery was not correctly registered by the vehicle. For example, if the technology or battery capacity are not entered correctly, the BMS cannot use the correct algorithm. If the battery is not even registered as new by the vehicle, it could be the case that the battery is not detected as new and therefore its full potential is not used.

You can find out more about this topic in our article about the risks of replacing a start-stop battery with a conventional battery.

Factors which are independent of the battery

There are also factors which interrupt the start-stop function, which do not depend on the battery:

- The safety belts are not being worn

- The car doors or the hood are not properly closed.

- The parking assistant is active

- The car is driving up a steep hill (gradient too large)

If the start-stop function fails very often, or does not activate at all, it is advisable to visit a workshop as soon as possible. In this case, with a battery test, the experts can find out whether the battery needs to be replaced.

-

How automatic start-stop works

What is automatic start-stop and how does it work?

Automatic Start-Stop: A technical innovation which helps the environment

The idea behind the start-stop system is simple: If the engine is stopped for short periods, for example while waiting at traffic lights, fuel consumption and emissions are reduced. In this way, the automatic start-stop system helps to save fuel and protect the climate. With this technology, CO2– emissions can be reduced by 3 – 8%. The benefits to the environment and improved efficiency have caused a rapid spread of automatic start-systems to all classes of vehicle. In view of the more stringent EU regulations on pollutant emissions of motor vehicles, automotive manufacturers are also increasingly implementing intelligent start-stop systems in their ranges.

How automatic start-stop systems work

The start-stop system detects when the car is stationary and on the basis of sensors it determines a series of other factors about the operating mode of the vehicle. If the driver has stopped at a traffic light and sets the transmission to neutral, the start-stop system stops the engine. With some more recent models, the engine even switches off if the speed falls below a certain value. Although the engine, and therefore the primary source of power for all systems is switched off, all of the electrical consumers and assistants are still supplied with power. This is provided by the battery of the vehicle. As soon as the clutch is actuated, the automatic start-stop system restarts the engine. For vehicles with automatic or dual clutch transmissions, the automatic start-stop system responds to actuation of the brake alone. If the vehicle is braked to a standstill and the driver’s foot remains on the brake pedal, the automatic start-stop system stops the engine. When the brake is released, the automatic system starts the engine again.

Sensors control the automatic start-stop system

An automatic start-stop system obtains its information about the driving status from various sensors. A neutral gear sensor, wheel speed sensor and crankshaft sensor provide information about whether the car is moving or stationary. The engine controller coordinates the start-stop processes and harmonizes them with the engine management system. The electronic battery sensor (EBS) communicates data about the state of charge, voltage and battery temperature. As the voltage in the onboard network briefly falls each time that the engine is started, compensation is necessary to ensure the proper function of important devices and electronic assistants. . In order for the starter to withstand the stresses which are associated with the increased number of starts and not wear out prematurely, components of the starter unit which are subjected to particular stress are reinforced and designed for a long service life. This applies to the bearings, gear unit and engagement mechanism of the starter.

Recuperation and automatic start-stop systems New battery generations for innovative technologies

While conventional batteries reach their limits even in vehicles with automatic start-stop systems, batteries with AGM technology were specially designed for vehicles, which not only have start-stop technology, but also an energy recover (recuperation) system as well as other fuel-saving systems. A battery with AGM technology is able to accept the energy which it receives via recuperation with high efficiency. In contrast, batteries with EFB technology are only designed for cars with entry-level automatic start-stop systems.

This may also interest you: When is an upgrade to AGM worthwhile?

Recuperation – how electricity is generated from braking energy

During recuperation, or recovery of braking energy, electrical energy is generated as soon as the vehicle brakes and the engine goes into thrust mode. In cars with recuperation, the generator feeds the recovered energy back into the battery in order to use this to operate the comfort functions during the subsequent stop phase. With the use of this efficient technology and a powerful AGM battery, greater fuel savings can be achieved and emissions can be reduced further than with simple start-stop systems. To increase overall efficiency even further, in some vehicles, the generator, which normally runs all the time (and consumes engine power) is decoupled during acceleration phases. Therefore, the entire motor power is available for acceleration and the engine can work especially efficiently. In this phase, all electrical functions are powered by the battery – which again shows the importance of a powerful battery which is matched to the energy management system of the vehicle for modern onboard networks.

-

Start-stop reduces emissions

Save fuel with start-stop to achieve EU climate targets

In 2007, the European Council presented a concept which is intended to sustainably reduce fuel consumption and reduce the associated emissions. The private car regulation which was adopted uses various measures to achieve the target value. These include environmentally compatible coolants for air conditioning systems, as well as equipment of vehicles with energy-saving LED lights. A further important technology for reduction of CO2 emissions is the use of automatic start-stop systems.

The first start-stop systems: All beginnings are difficult

As early as the beginning of the 1970s, Toyota was the first automotive manufacturer to present a start-stop system as a response to the oil crisis. The idea: Automatic start-stop systems save fuel and therefore money. This was a sensible idea in view of the price increases for gasoline and diesel fuel due to the oil crisis. VW and Audi were also quick to recognize the advantages of a start-stop system and presented a semi-automatic start-stop system at the beginning of the 1980s. However, due to lack of acceptance by customers, the first start-stop systems soon disappeared from the market.

It was only at the turn of the century, that leading automotive manufacturers turned to this technology again and developed it further. As well as the economic benefits which start-stop technology provides to drivers, this time it was the planned EU climate-related legislation which caused the revival of automatic start-stop systems.

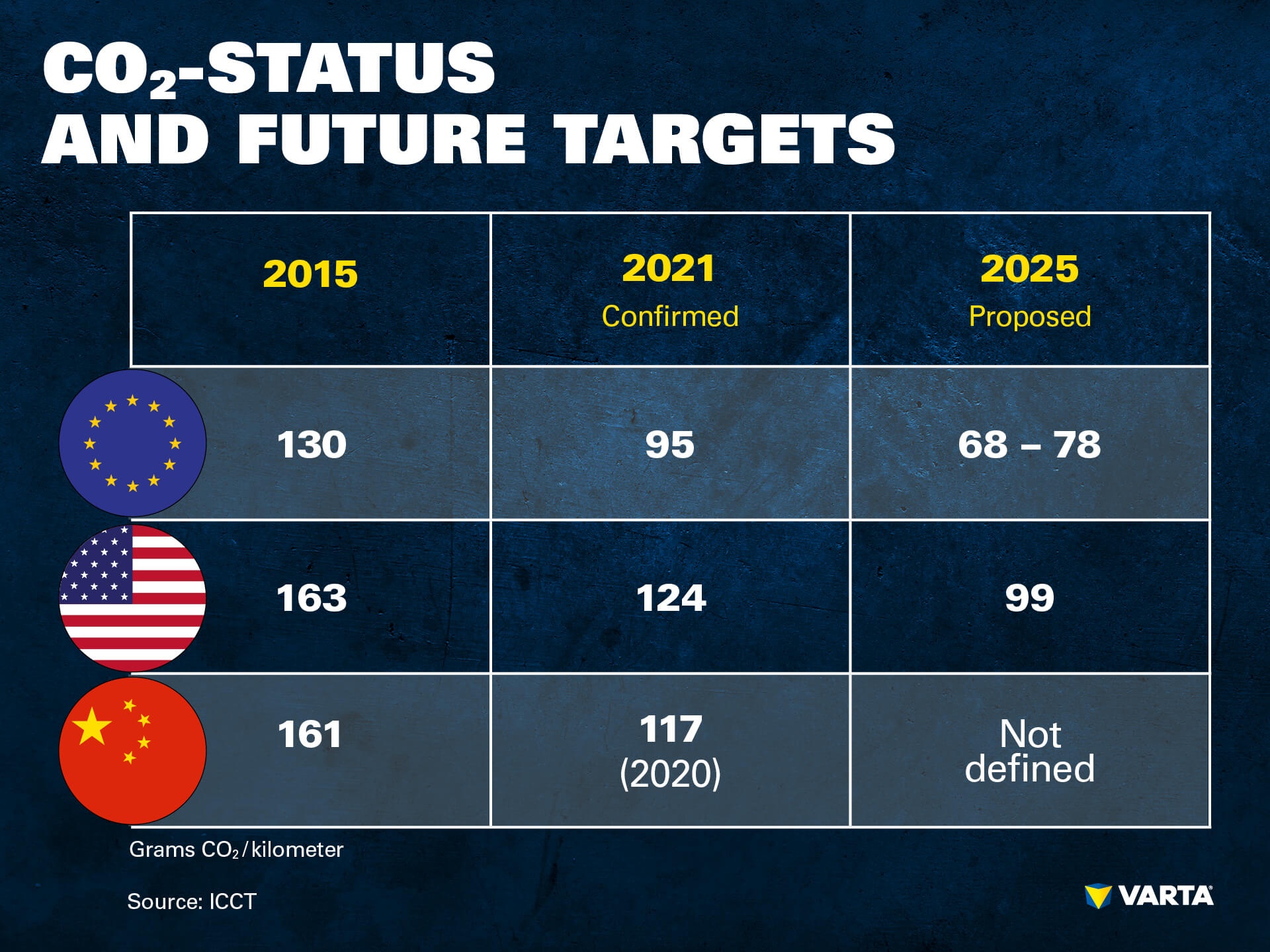

Strict CO2 regulations: Automotive manufacturers use environmentally friendly technologies

The EU regulation for the reduction of CO2 emissions specifies that as of 2021, private cars may only emit 95 grammes of carbon dioxide per kilometer. From 2025, this limit will be reduced to between 69 to 78 grammes. For comparison: In 2015, car models emit an average of 130 grammes of carbon monoxide per kilometer.

For the coming years, the USA and China are also aiming to reduce CO2 emissions. While CO2 emissions in the USA in 2015 were 163 grammes of carbon dioxide per kilometer, in 2021, the value should only be 124 grammes. For 2025, a reduction of CO2 emissions to 99 grammes per kilometer is aimed for.

In 2015, climate-damaging carbon dioxide emissions by private cars in China were 161 grammes per kilometer. By 2020, the value should be only 117 grammes per kilometer.

As compact cars, sports cars and large sedans have different emissions, the limit value relates to the entire European vehicle fleet. The average weight of all the vehicles which an automotive manufacturer has in its range is used as the basis for calculation of the manufacturer-related limit value. Fines will be levied if the limit values are exceeded. Ecologically beneficial innovations with which a manufacturer contributes to reducing CO2 emissions have a positive effect on the limit value. These include solar cells on vehicle roofs, as well as systems for heat recovery from exhaust gases.

Less greenhouse gases with start-stop systems

Depending on the style of driving, start-stop technology can achieve fuel savings of up to 15%. However, the effectiveness of the system depends on many factors, including the area of use. During urban journeys, the automatic start-stop system causes the engine to switch off as soon as it is idling.

In addition to saving fuel, this enables CO2 emissions to be reduced by 3 – 8%.

Interesting facts about start-stop

Did you know that there are various types of stop-start systems? In addition to simple start-stop technology, there is also a system which thanks to regenerative braking (recuperation), the kinetic energy which is generated by the vehicle is partly converted to electrical energy which is then supplied to the battery. -

The new role for car batteries

Car batteries then and now: an overview

Good and simple: Requirements of car batteries up to 1990

Until a few decades ago, apart from the starter and the ignition, there was only a small number of devices which had to be supplied with electricity. Except for the vehicle lighting, radio and windshield wipers, in many small and compact cars, there were not many other consumers. Even in concept cars, in those days’ engineers tended to concentrate on a futuristic design and innovative engine technology rather than on electronic assistants.

New technologies, greater demands: The role of batteries from the middle of the 1990s

It was only in the middle of the 1990s that features such as electric windows and central locking systems also became established in the compact class. Since then, the number of electrical consumers has continued to increase. These days, owners of new cars are supported by a large number of electronic assistants. In addition to electrical consumers such as infotainment and navigation systems, which have been available in vehicles for a long time, especially new vehicle technologies such as start-stop systems contribute to the increased load on the battery.

Cars as apps on wheels: Requirements of modern batteries

Vehicles from the present generation are often referred to as ‘apps on wheels’. A modern car now has an average of 50 units which are controlled by the control electronics, as well as a further 150 electrical consumers. Demands on driving as an experience have grown. Drivers expect a high level of convenience, extensive safety, communicative networking and a high level of environmental compatibility. Modules such as start-stop systems, recuperation (recovery of braking energy), infotainment and parking assistants have to be controlled and reliably supplied with electrical power. For the equipment of a vehicle with a battery, adaptation to the existing technical infrastructure is becoming increasingly important. Car batteries have to keep pace with developments in the automotive field. This can only be achieved with innovative battery technologies such as EFB and AGM.

A look to the future: New batteries are already available

The development of new battery technologies is not only necessary for electric vehicles, but rather, in particular for the coming generation of combustion engines, as the growing number of electronic systems demands an increasing amount of power from the battery. While in 2017 the market share of electric vehicles (incl. plug-in hybrids) was 1.6% lag, start-stop technology is currently becoming increasingly widespread in vehicles with combustion engines. This requires a new battery generation. Even now, 90% of all new vehicles are equipped with start-stop technology and by 2020, 30% of all vehicles will have start-stop technology.

A further trend in addition to the previous start-stop technology and electro mobility is autonomous driving. Even though the onboard computer will only take over completely in the distant future, in the near future drivers will be increasingly assisted by intelligent systems and will hand over a part of their control over the vehicle to the control unit. This involves the necessity for a high performance and reliable power supply.

Batteries in 2020: Service and maintenance must keep pace

Not only cars are becoming more complex due to upgrades with electronic systems: service and battery replacement also requires new interfaces. For technical reasons, modern batteries are often installed in the trunk or under seats, which makes the replacement and servicing of car batteries considerably more difficult. Readout of the data which is provided by the vehicle Battery Management System (BMS) takes time. Compatible diagnostic devices are required to fully read out the control units and to enable the frequently required registration of the battery in the system. As a result, regular further training in the field of battery technology and optimization of workflows in the workshop are necessary in order to be able to offer customers a first class and well-founded service in the future.

The VARTA® Partner Portal: Rapid assistance on the subject of batteries

With the VARTA Partner Portal, VARTA® Automotive provides professional garages valuable assistance with all questions related to the topic of batteries. As well as extensive information about the installation location of the battery in the vehicle, VARTA® Automotive also provides detailed instructions for battery replacement for almost all types of vehicle.

-

Start-stop battery replacement

Which is the best replacement battery for automatic start-stop systems?

The energy consumption of modern vehicles is increasing and the increasing number of electronic components and comfort systems puts a great load on the battery. In addition, legal requirements to reduce CO2 emissions forced manufacturers to introduce automatic start-stop systems.

Only high performance car batteries such as EFB or AGM batteries can deal with these increased requirements and provide a stable power supply in the vehicle. A battery for a start-stop system can only be replaced with a battery of the same type. In the case of an EFB battery, an upgrade to an AGM may be advisable. However, under certain circumstances, an AGM battery may be suitable for vehicles without start-stop technology.

With the VARTA Battery Finder you can quickly find the right battery.

Below, we have summarized the various battery technologies and the right replacement batteries, as well as why an upgrade can be worthwhile.

Car battery Technologies

Conventional starter batteries

Conventional lead-acid batteries are tried and tested products, which have been proven in millions of vehicles for decades. These days, almost all batteries are maintenance-free. Beyond a regular check by your workshop in order to detect an imminent failure, no other maintenance is needed. If an older battery is not maintenance-free, it must only be serviced by specialists.

With good care, a lead-acid battery can last for many years and they are still widely used in vehicles without start-stop systems and with a moderate number of electrical components.

EFB Batteries

EFB batteries are higher performance versions of conventional starter batteries.

Thanks to the enhancements surrounding the plates with a polyester scrim and an improved formulation of the active material, these can be used more effectively. This also results in a slower increase of the internal resistance of the battery over its lifetime than is the case with a conventional battery. EFB batteries are widely used in vehicles with entry-level start-stop systems, usually without recovery of braking energy.

AGM batteries

AGM batteries score with their high performance and durability. In an AGM battery, the glass fiber mat which is used as a separator absorbs the electrolyte, which makes it impossible for the battery acid to leak. The plates of AGM batteries are installed with a defined compression. This ensures an optimal connection between the acid and the plates over the entire life of the battery. In addition, the compression prevents the loss of active material and makes the battery especially robust for demanding applications.

AGM batteries are used in vehicles with advanced automatic start-stop systems and recovery of braking energy.

Only replace an EFB with an EFB or AGM battery

Starter batteries with AGM or EFB technology are designed to meet the requirements of vehicles with start-stop systems. Normal car batteries cannot deal with the high demands which occur due to discharge during the stop phases. Replacement with a normal battery instead of an AGM or EFB, results in rapid deterioration of the battery, and a breakdown is inevitable. For optimum function, a battery must be used, which is compatible with the vehicle’s battery management system. An upgrade from an EFB to an AGM battery is possible and increases the efficiency of the automatic start-stop system and results in increased efficient fuel consumption.

A vehicle with an AGM battery needs and AGM battery

Cars with automatic start-stop systems and energy recuperation create heavy demands on the battery. An AGM battery can also deal with the large number of cycles which are caused by the automatic start-stop system and is also suitable for charging with regenerative braking energy.

An EFB battery is usually used with a higher charge level so that storage of energy from recuperation is not possible, or is only possible to a limited extent. A powerful AGM battery with OEM quality guarantees high reliability and better driving experience.

When is an upgrade worthwhile?

AGM batteries satisfy the hunger for energy

Modern compact and medium-sized cars are often equipped with many electronic assistants and comfort features such as heated seats or mirrors. As well as these, there are components such as navigation systems and central locking systems, which are often standard features, even in small cars. Premium class vehicles, SUVs and sports cars are equipped with even more electrical components, which the battery must supply in all driving situations and in all weathers. In such cases, an upgrade to an AGM battery may be worthwhile, even for vehicles without automatic stop-start technology in order to ensure increased reliability.

Seasonal vehicle use

Many convertibles, vintage vehicles and second cars are often only used in summer and are mothballed for several months during winter. During this period, the battery is not charged by the alternator, so it is advisable to maintain the charge with a compatible battery charger. An AGM can be recharged much better and provides adequate capacity for longer, as acid layering and sulfation are less prone to sulfation due to the bound electrolyte. This ensures a successful start to the season.

Upgrade quick-check

- Does the vehicle have extensive electronic equipment?

- Is the vehicle equipped with additional, retrofitted electronic devices?

- Are devices, e.g. mobile phones, often charged in the vehicle?

- Do you often drive under extreme weather conditions?

- Do you often drive short distances or are often in traffic queues?

- Would you be prepared to pay more for a product with a better long-term benefit (service life)?

If you have answered any of these questions with “yes”, an upgrade to an AGM is recommended.

Find out more about when replacement with an AGM battery is worthwhile, even without a start-stop system.

-

Battery replacement

Battery replacement – step-by-step

When the car battery is weak, it is time for a battery replacement. Which steps are to be considered and why is it so much more complicated with modern cars? Car batteries are usually located under the bonnet. However, in modern vehicles the starter battery can also be installed in other places in the vehicle. These days, only about 58% of batteries are installed under the bonnet. About 40% are located in the boot and in the remaining vehicles the battery is even in the passenger cabin. So how do you replace the battery?

Which battery do I need?

A new battery has to be bought before the battery replacement. Here, the recommendations of the vehicle manufacturer are relevant. The following criteria are relevant for the choice of battery:

Battery group sizes

The battery group size describes the standardized size of the car battery, but often several sizes of battery can be installed in a vehicle. For example, the starter battery for a diesel vehicle is usually larger than that for a comparable petrol-driven vehicle. The situation is similar if the vehicle is available with different engine types. Here too, the battery mount is usually designed to accommodate various sizes of battery.

Electrical voltage

With only a few exceptions, in the automotive sector there are now only 12V batteries. In contrast, some vintage cars require special 6V batteries. In this case, a 12V battery cannot be installed, as the electrical components would be destroyed by the higher voltage.

Large commercial vehicles usually have a 24V system. For this, two 12V batteries are connected in series.

Cold start current

A high cold start current (CCA) ensures good starting and is especially important in cold winter weather. The value on the label is determined by a standardized test procedure (in Europe by EN 50342-1) at a temperature of -18°C.

Capacity

The second important value on the label describes the capacity (Ah) of the battery. The capacity is determined with a standardized test procedure and describes how much charge can be withdrawn from the battery before it is completely discharged.

While the cold start current was primarily important for conventional vehicles, in modern vehicles with a large number of electrical components and start-stop systems, the capacity is becoming increasingly important. Learn more about the best battery replacement for a start stop vehicle.

For a small car with only a few electrical components, a battery with 40 – 45 Ah is sufficient. Premium class vehicles and sports cars are equipped with batteries with capacities of up to 110 Ah. The charge capacity of a car battery reduces with increasing age and depends on factors such as ambient temperatures and humidity.

How a conventional car battery works.

How do I find the best battery for my vehicle?

With the wide range of starter batteries with various technologies and power classes, the choice is often difficult. The VARTA® Battery Search makes it easy to select the right battery.

How do I install the new battery?

The instructions by the vehicle manufacturer must be followed for the installation of the new battery. Please also note the information from the battery manufacturer in the booklet for the safe handling of batteries. To prevent reverse polarity, the arrangement of the positive and negative terminals should be noted before removing the old battery. Of course, the engine must also be turned off and key removed.

- Before starting work on the battery, please put on protective glasses. Avoid direct contact with any battery acid which may have escaped.

- First remove the ground cable. This safely prevents a short circuit between the positive terminal and the vehicle body.

- Check the battery compartment for corrosion. Also thoroughly inspect the brackets for rust and damage. Clean the battery compartment and repair as necessary. Corrosion in the area of the battery can indicate leaked battery acid. In this case a workshop should investigate the reason for this.

- Remove surface rust and dirt from the battery terminal clamps, as this causes increased contact resistance and therefore considerable malfunctions or premature battery failure.

- Take care that the terminal clamps are firmly fitted in order to eliminate contact interruptions due to vibrations. When connecting the terminal clamps, care must also be taken that the battery terminals are not damaged by torsion or other mechanical stresses.

- Take care that the battery is properly seated on installation. Tighten the clamps with a torque wrench. The correct torque can be found in the vehicle manual.

- Before connection, check the correct polarity of the cables again. First connect the red cable to the positive terminal and then connect the black ground cable to the negative terminal.

After the battery replacement it might be necessary to recalibrate internal car systems such as airbags, sensors and other comfort functions. This is especially true for more modern cars that are equipped with lots of technical systems or start stop. For such cars it is advisable to let the battery replacement be handled by a professional garage.

How do I dispose of the old battery?

Car batteries are hazardous waste and do not belong in domestic garbage. The disposal of batteries is regulated by law. Car workshops and recycling centers accept old batteries. Did you know that 99% of a battery can be recycled and about 80% of a new battery consists of recycled material? This recycling system prevents pollution of the environment.

-

Is an AGM battery better?

Is an AGM battery worthwhile without automatic start-stop technology?

AGM batteries primarily utilize their high performance in combination with start-stop technology. However, the strengths of an AGM battery can also be used even if there is no start-stop system on board: This technology provides larger power reserves, from which conventional vehicles can also benefit, e.g. due to a longer service life of the battery.

Encapsulated AGM batteries are maintenance free and leak-proof, as the electrolyte of an AGM battery is bound in an absorbent separator made of glass fibers. No battery acid can escape, even if the battery is damaged. This prevents subsequent damage to the bodywork (e.g. rust) or other adjacent components.

Advantages of switching to an AGM battery

As well as the advantages which have already been mentioned, there are other reasons to upgrade to an AGM battery. The following circumstances make replacement with an AGM battery advisable:

- Large numbers of short trips of less than 10 km or with an annual mileage of less than 10,000 km do not allow the alternator enough time to adequately recharge the battery. Each time the battery is not recharged to the full SOC (State of Charge) the harder it makes it for the battery to start the vehicle the next time.

- If the vehicle is only used on a seasonal basis, an older conventional starter battery starter battery can discharge prematurely. This is especially the case if there are unfavorable conditions at the storage location and the charge is not maintained with a battery charger. An AGM battery can withstand long standstill times better, as with this technology, layering cannot occur in the electrolyte which is bound in the separator, so that there is less sulfurization. This means that an AGM battery is easier to recharge than a wet battery after a long standstill period.

- An AGM battery can also withstand extreme external temperatures and has large power reserves. A conventional starter battery responds to great heat and cold with a rapid decrease in capacity and discharges faster.

- If the vehicle is equipped with a large number of non-standard electrical devices, which have an increased power consumption, e.g. a sophisticated sound system, the AGM battery provides the vehicle with the necessary power, which a conventional wet battery cannot provide.

AGM Batteries – The first choice for light commercial vehicles

- In commercial use, vehicles are often used for multiple shift operation. An AGM battery can withstand the higher loads in multiple shift operation better than a normal starter battery.

Urban trucks are also often provided with electrically powered components and special equipment. A conventional starter battery quickly reaches its limits and deteriorates due to decomposition of the active material which is relevant for its capacity. Due to the special design of the cells and a special mixture for the active material, an AGM battery can withstand more and deeper charging cycles than a conventional battery.

- Urban deliveries and taxis often primarily involve short journeys – in all kinds of weather. An AGM battery starts the vehicle reliably and also meets the demands of commercial operation.

Automatic start-stop systems are more effective with an AGM battery

Vehicles with simple start-stop systems without recovery of braking energy (recuperation) are usually equipped with an EFB battery. However, even in this case, replacement with an AGM battery is worthwhile: The start-stop technology technology operates reliably and without malfunctions. Last but not least, AGM batteries impress with their high load capacity: Over its entire service life, an AGM battery has a better charge acceptance than an EFB battery.

Upgrade quick-check

- Does the vehicle have extensive electronic equipment?

- Is the vehicle equipped with additional, retrofitted electronic devices?

- Are devices, e.g. mobile phones, often charged in the vehicle?

- Do you often drive under extreme weather conditions?

- Do you often drive short distances or are often in traffic queues?

- Would you be prepared to pay more for a product with a better long-term benefit (service life)?

If you have answered any of these questions with “yes”, an upgrade to an AGM is recommended.

Did you know?

Start-stop technology equipped with an EFB battery only switches off the engine in 39%* of all cases in comparison with an AGM battery. The combination of an AGM battery and a start-stop system is economical, powerful and dependable.

*Clarios study

-

Battery technologies

Battery types – Lead acid, AGM, EFB

Starter batteries have proved themselves in millions of cars throughout the world. With continuous innovations and further developments, over the years classic wet batteries have increased in performance, reliability and versatility. EFB and AGM batteries are new battery types, which cater for the increased demands of the present generation of vehicles.

AGM, EFB, Lead Acid: Three different battery types – many common features

AGM and EFB batteries are characterized by their high performance. In spite of their different technological approaches, the latest generation of battery types have further positive features in common: They need less maintenance and are more reliable than 10 years ago – thanks to advances in battery technology.

Just a few decades ago, the acid level in a car battery had to be regularly checked and topped up with distilled water if necessary. With modern, maintenance-free batteries, water loss is so low that topping up with distilled water is not necessary during the life of the battery.

Starter batteries, EFB batteries and AGM batteries: The differences between battery types

- Wet cell batteries (SLI) – proven and economical

- EFB batteries – many charging cycles and long life

- AGM batteries – high performance and load capacity

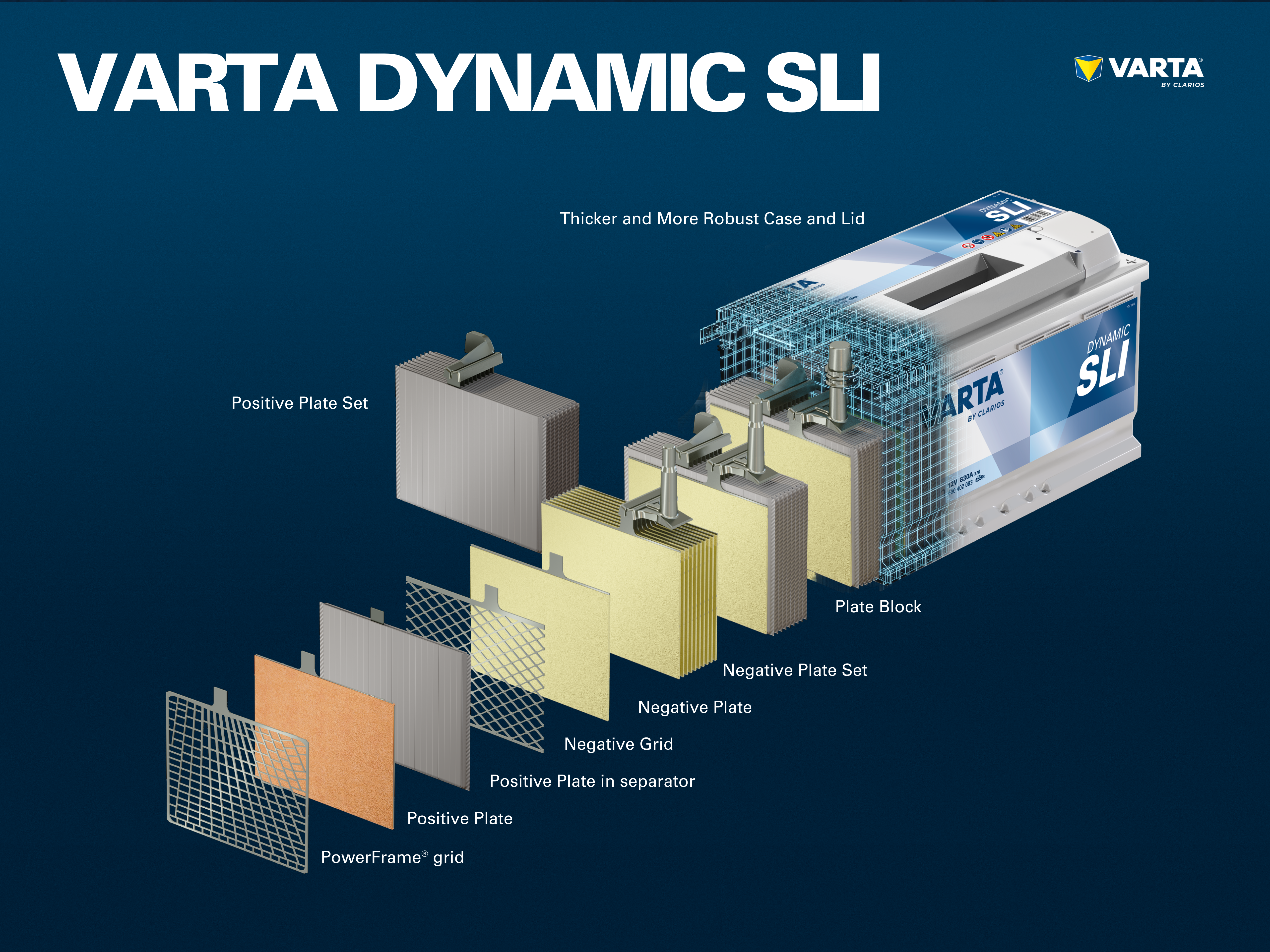

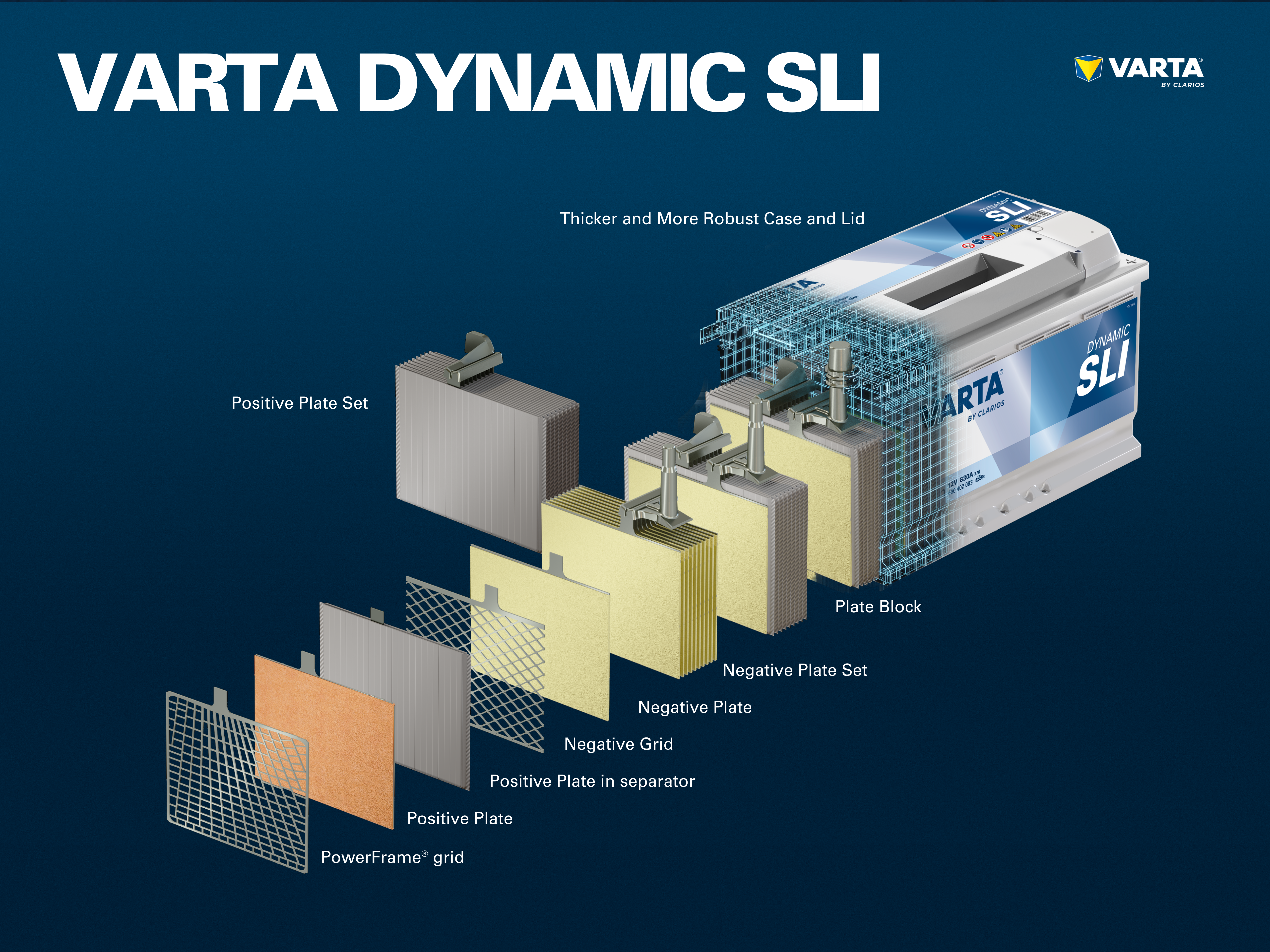

A conventional starter battery consists of six battery cells. A battery cell, also referred to as a plate block, consists of a positive and a negative set of plates, which in turn consists of several electrodes.

A positive electrode consists of active material made from lead oxide and a positive grid made of lead alloy. The grid structure gives the electrodes a solid structure and at the same time serves as an electrical conductor. The active material is immersed in an electrolyte, a mixture of acid and distilled water.

A negative electrode also consists of active material, however in this case made of pure lead, and a negative grid. The electrodes with different polarities are separated by a separator. The required battery capacity is achieved by connecting the individual plates in the cell in parallel. Connecting the individual cells in series produces the required voltage of 12 Volt.

Do you want to know more? You can find out how a battery functions in our article about the structure and function of starter batteries.

Conventional batteries such as lead-acid batteries are the most common types of battery. This technology is often referred to as SLI, which relates to the main functions of a vehicle battery: Starting, Lighting, and Ignition. They are suitable for vehicles without start-stop technology and a moderate number of electrical consumers.

EFB batteries are an optimized, higher performance version of the wet battery. The abbreviation “EFB” stands for “Enhanced Flooded Battery”. Here too, the plates are insulated from each other with a microporous separator. Between the plate and the separator there is also a polyester scrim. This material helps to stabilize the active material of the plates and extend the life of the battery. EFB batteries have a large number of possible charging cycles and provide more than double the partial and deep discharge performance in comparison with conventional batteries.

EFB batteries are often installed in vehicles with simple automatic start-stop systems. Due to their superior performance batteries with EFB technology are also increasingly used as replacements for conventional lead-acid batteries.

AGM batteries are versatile, have high performance and are designed for high demands. In principle, the structure of an AGM battery is the same as that of a wet cell battery. However, in an AGM the electrolyte is no longer free-floating, but rather is bound in a special glass fiber separator – hence the name “Absorbent Glass Mat”. The large contact area contributes to the power output and also makes the battery leak-proof. Due to its construction, the battery is sealed airtight. This feature enables internal recombination of oxygen and hydrogen, so that there is no water loss. To protect against excess pressure, the individual battery cells are equipped with a safety valve, so that they remain safe, even in case of a fault.

With regard to their service life, AGM batteries have significant advantages over simple starter batteries. An AGM battery can withstand three times more cycle life than a conventional starter battery. A further advantage of AGM batteries is that they are not dependent on their position, as due to the binding of the electrolyte, no liquid can escape. Even if the battery case is fractured, no battery acid can escape.

AGM batteries are ideal for vehicles with automatic start-stop systems with braking energy recovery (recuperation), as a conventional starter battery cannot handle the high power demands of these systems. AGM batteries are also the right choice for cars with high energy consumption and a large number of electrical consumers.

Which battery for which vehicle?

In the VARTA® Partner Portal, our partner workshops can quickly find the right replacement battery, its position in the vehicle, as well as installation and removal instructions for most vehicles which are in use in Europe. The VARTA® Battery Finder is also a helpful tool for our end customers to decide which is the right replacement battery for their vehicle.

Under certain circumstances, an upgrade to a different battery technology may be worthwhile. Here, you can read about when this is the case. An AGM battery must always be replaced with an AGM battery. If a conventional battery is installed in a start-stop vehicle, a significant reduction of battery life or restrictions in the function of the vehicle’s Energy Management System must be expected. This also applies if the start-stop function is deactivated.

-

Battery glossary

Special car battery terms explained understandably

Absorbent Glass Mat (AGM)

The mat of micro glass fibers which is used for absorbing the sulfuric acid in lead batteries. The distinguishing feature of an AGM battery.Acid Stratification

When charging a lead-acid cell, high density acid is produced in the plates. This heavy acid drops as a result of gravitation to the lower part of the cell while lower density acid rises to the top of the cell. This stratification of acid can cause loss of capacity &/or caused by battery.Active Material

The active material in the positive plates is lead dioxide and that in the negative is metallic sponge lead. When an electrical circuit is created, these materials react with sulfuric acid during charging and discharging according to the following chemical reaction: PbO2 + Pb + 2H2SO4 = 2PbSO4 + 2H2OAmpere (Amp, A)

The unit of measure of the electron flow, or current, through a circuit.Ampere (Amp) Hours

A unit of measure for a battery’s electrical storage capacity, obtained by multiplying the current in amperes by the time in hours of discharge. (Example: A battery which delivers 5 amperes for 20 hours delivers 5 amperes x 20 hours = 100 Amp-Hr of capacity.)Battery Case

Battery box containing the plate blocks, the connectors and the electrolyte.Battery Charger

Unit supplying electrical energy to a secondary battery. Product release: Battery Chargers.Battery Test

Battery Test describes the test for determining the charging condition and electrolyte level of lead batteries with liquid electrolyte. The charging condition is determined by measuring of the acid density.Capacity

The ability of a fully charged battery to deliver a specified quantity of electricity (Amp-Hr, AH) at a given rate (Amp, A) over a definite period of time (Hr).Cell

The basic electrochemical current-producing unit in a battery consisting of a set of positive plates, negative plates, electrolyte, separators and casing. There are six cells in a 12-volt lead-acid battery.Charge Acceptance

The quantity of current in ampere hours which a battery in a defined charge state can accept at a specified temperature and charge voltage within a defined period.Circuit

The path followed by a flow of electrons. A closed circuit is a complete path. An open circuit has a broken or disconnected path.Cold Cranking Rating

Number of amperes a lead-acid battery at 0oF (-17.8°C) can deliver for 30 seconds and maintain at least 1.2 volts per cell. Very important for the operation of snowmobile batteries.Container

The polypropylene or hard rubber case which holds the battery plates, straps and electrolyte.Corrosion

The destructive chemical reaction of a liquid electrolyte with a reactive material – e.g., dilute sulfuric acid on iron, producing corrosion products such as rust.Cover

The lid for the containerCurrent

The rate of flow of electricity, or the movement of electrons along a conductor. The unit of measure for current is the ampere.Cycle

In a battery, one discharge plus one recharge equals one cycle.Deep Discharge

State in which a cell is fully discharged using low current, so that the voltage falls below the final discharging voltage.Discharge

When a battery is delivering current, it is said to be discharging.Electrolyte

In a lead-acid battery, the electrolyte is sulfuric acid diluted with water. It is a conductor that supplies water and sulfate for the electrochemical reaction: PbO2 + Pb + 2H2SO4 = 2PbSO4 + 2H20Fading

Long-term loss of capacity during use.Failure

A state in which a battery no longer functions satisfactorily. There are several forms of failure.Failure, permanent

A state in which a cell or battery cannot be recharged to a satisfactory level.Failure, reversible

A failure condition that can be remedied by using particular electrical procedures or by reconditioning.Final charging current

The final charging current is the current at the end of an IU charging operation (gassing current).Final discharging voltage

Indicates the lowest allowable voltage level that a battery or cell can be discharged to. Discharging to below this cutoff voltage (deep discharge) can impair or (through pole reversal) destroy the electrochemical cell in the case of various battery types (e.g. lead, Ni/Cd, NiMH).Forming

Initial electrical charging for converting the active masses into the charged state (e.g. PbSO4 -> Pb (-) und PbO2 (+) ).Frame

The reinforced outer parts of a battery grid.Grid

The lead alloy framework that supports the active material of a battery plate and conducts current.Ground